Understanding Acrylic Sheets and Plexiglass

What Are Acrylic Sheets? – Definition and key properties

Acrylic sheet or plexiglass stands as a modern marvel in the world of materials—offering a blend of durability, transparency, and versatility that is hard to match. These sheets are crafted from polymerized methyl methacrylate, a substance prized for its clarity and strength. In fact, acrylic sheets are often dubbed “the glass alternative” because they can be shaped and polished to mimic glass while providing superior impact resistance. This resilience makes them ideal for applications ranging from architectural glazing to creative signage.

Understanding the key properties of acrylic sheet or plexiglass reveals why it has become a preferred choice across industries. It boasts excellent optical clarity, allowing up to 92% of light to pass through—crucial for display cases, skylights, and even aquariums. Additionally, its lightweight nature—about half the weight of glass—facilitates easier installation and handling. The material’s resistance to UV rays and weathering further extends its lifespan in outdoor environments, making it a sustainable investment for South African projects. Whether for innovation or everyday practicality, acrylic sheet or plexiglass continues to shape the future of design and construction.”

Plexiglass Explained – Overview and relationship to acrylic sheets

Plexiglass, often regarded as the star of modern materials, is actually a specific form of acrylic sheet. While many refer to it interchangeably, understanding the subtle distinctions can unlock new possibilities in design and construction. Plexiglass is a brand name that has become synonymous with acrylic sheet or plexiglass, but it also represents a type of high-quality, transparent polymer that’s renowned worldwide.

At its core, plexiglass is a versatile, lightweight alternative to glass, with properties that make it uniquely suited for innovative applications. Its relationship to acrylic sheets is rooted in its composition—both are made from polymethyl methacrylate (PMMA)—but plexiglass tends to be associated with premium-grade sheets that meet strict standards for clarity and impact resistance. This makes it a favorite among architects, artists, and engineers alike.

What truly sets acrylic sheet or plexiglass apart is its ability to be shaped into complex forms without losing its optical clarity. Whether used for intricate signage, protective barriers, or even artistic installations, the material’s adaptability remains unmatched in the realm of transparent plastics. When considering the various uses, keep in mind:

- High optical transparency, passing up to 92% of light

- Exceptional durability against impacts

- UV resistance for outdoor longevity

Differences Between Acrylic and Plexiglass – Material composition and performance distinctions

When it comes to transparent plastics, understanding the subtle yet crucial differences between acrylic sheet or plexiglass can be a game-changer for your project. Despite their reputation for being interchangeable, these materials have distinct characteristics rooted in their composition. Acrylic sheets, including plexiglass, are made from polymethyl methacrylate (PMMA), a polymer celebrated for its optical clarity and versatility. But here’s where the plot thickens: plexiglass is often viewed as a premium-grade acrylic sheet, boasting superior impact resistance and a clearer finish. It’s the material of choice for those who demand durability without sacrificing aesthetics.

Performance-wise, acrylic sheet or plexiglass excels with high light transmission—up to 92%—making it perfect for display cases, signage, and protective barriers. It’s also UV resistant, ensuring outdoor installations stay pristine for years. Here’s a quick rundown of what sets them apart:

- Material composition—both are PMMA-based but vary in quality standards.

- Impact resistance—plexiglass tends to be tougher, reducing breakage risk.

- Clarity and optical quality—plexiglass often offers higher transparency.

In South Africa, where outdoor durability is key, choosing the right acrylic sheet or plexiglass can mean the difference between a fleeting project and a lasting masterpiece. Whether you’re designing a modern storefront or a bold artistic installation, knowing these distinctions ensures you select the perfect material for your needs—without settling for mediocrity.

Common Variants and Types – Cast vs. extruded acrylics

Understanding the nuances of acrylic sheet or plexiglass involves more than just recognizing their glass-like allure. The common variants—cast and extruded acrylics—each tell a different story, crafted through distinct processes that influence their destiny in your projects. Cast acrylic, born from pouring liquid monomers into molds, emerges with a rich, deep clarity and remarkable stability, making it ideal for intricate designs and high-end applications. Its surface boasts a luxurious smoothness, often rivaling the finest glass, yet with a resilience that defies expectations.

In contrast, extruded acrylic is shaped through a continuous molding process, allowing for rapid production and consistent quality. This variant tends to be more impact-resistant, a trait that lends itself well to outdoor installations and high-traffic environments. Its affordability and ease of fabrication do not compromise its appeal, making it a go-to choice for many industries.

- Cast acrylics are typically thicker and exhibit superior optical clarity, perfect for display cases and artistic installations.

- Extruded acrylics, with their uniformity, excel in applications demanding impact resistance and cost-efficiency.

Choosing between these variants hinges on understanding their core differences—each a symphony of material science and craftsmanship—ensuring that your choice of acrylic sheet or plexiglass elevates every project to an enduring masterpiece.

Benefits of Acrylic Sheets and Plexiglass

Durability and Impact Resistance – Why they’re tough and long-lasting

In the realm of building materials, few options combine resilience with versatility quite like acrylic sheet or plexiglass. These materials have transcended their initial purpose, becoming staples in both commercial and residential applications across South Africa. Their reputation stems from an impressive blend of durability and impact resistance, making them a smart investment for long-term projects. While their transparent beauty captivates the eye, it’s their toughness that truly stands out.

One of the most remarkable qualities of acrylic sheet or plexiglass is its impact resistance. Unlike glass, which shatters upon impact, acrylic can withstand significant force without cracking or breaking. This resilience ensures safety and longevity, even in environments prone to accidental knocks or vandalism. Its durability is further enhanced by resistance to UV rays and weathering, which means that outdoor installations remain clear and intact for years. This combination of strength and clarity makes acrylic sheet or plexiglass a preferred choice for everything from protective barriers to decorative fixtures.

In essence, the inherent toughness of acrylic sheet or plexiglass not only prolongs its lifespan but also reduces maintenance costs. Its ability to absorb shocks without losing integrity underscores why it’s a smart, sustainable choice. As a material that embodies both form and function, acrylic sheet or plexiglass continues to redefine the boundaries of what’s possible in design and construction — tough, long-lasting, and undeniably versatile!

Weather and UV Resistance – Suitability for outdoor applications

When it comes to outdoor applications in South Africa, the weather and UV resistance of acrylic sheet or plexiglass are truly game-changers. Unlike traditional materials that succumb to fading or degradation under relentless sunlight, acrylic boasts exceptional resistance to harmful UV rays. This means that whether you’re installing a vibrant signage display or a protective outdoor barrier, your acrylic sheet or plexiglass stays clear and resilient for years, even under the harsh African sun.

Additionally, acrylic’s weather resistance allows it to withstand extreme temperature fluctuations, rain, and wind without warping or losing its structural integrity. This durability makes it an ideal choice for outdoor furniture, garden features, or even bus shelters. To further emphasize its suitability, consider these key benefits:

- Superior UV resistance ensures long-lasting clarity and colour retention

- Outstanding weatherproofing protects against rain, wind, and temperature shifts

- Low maintenance requirements reduce ongoing upkeep costs

Choosing acrylic sheet or plexiglass for outdoor projects isn’t just about aesthetics; it’s about investing in a resilient, versatile material that thrives amid South Africa’s dynamic climate. Its ability to endure the elements while maintaining transparency and strength cements its reputation as the premier material for outdoor installations.

Optical Clarity and Transparency – Clarity advantages over glass

In the realm of transparent materials, few rival the luminous allure of acrylic sheet or plexiglass. Its optical clarity surpasses even that of traditional glass, offering a crystalline window into the world beyond. When sunlight dances upon its surface, the brilliance remains undiminished—no fogging, no yellowing, just pure, unblemished transparency that invites admiration.

This exceptional clarity isn’t merely aesthetic; it’s a testament to the material’s meticulous craftsmanship. Acrylic sheet or plexiglass provides a vivid, lifelike view that enhances signage, display cases, or architectural features. Unlike glass, which can shatter or crack, acrylic boasts a resilience that keeps your vision unobstructed for years to come.

For outdoor applications especially, the difference in optical purity is profound. Its high light transmission ensures that vibrant colors and intricate details shine through, unclouded by haze or distortion. This makes acrylic sheet or plexiglass an unrivaled choice for artistic installations, protective barriers, and innovative design projects awaiting the South African sun’s scrutiny.

- Superior optical clarity ensures a pristine view

- High light transmission enhances visual impact

- Resilience maintains transparency under harsh conditions

When choosing a material that combines durability with a clear, captivating appearance, acrylic sheet or plexiglass stands tall—an unobstructed portal to beauty and resilience in every application.

Lightweight and Flexible – Ease of handling and installation

When considering the versatility of acrylic sheet or plexiglass, one of its most compelling features is its lightweight and flexible nature. Unlike traditional glass, which can be cumbersome and fragile, acrylic sheet or plexiglass offers ease of handling that transforms installation from a daunting task into a straightforward process. This flexibility allows for seamless shaping and bending, making it an ideal choice for curved surfaces, custom displays, and architectural accents.

Handling acrylic sheet or plexiglass is remarkably less strenuous, reducing labor costs and installation time. Its pliability opens up creative possibilities that would be challenging with glass or other rigid materials. Whether you’re designing a solar shield, signage, or decorative feature, this material adapts effortlessly to your vision.

For projects demanding speed and precision, the inherent flexibility of acrylic sheet or plexiglass is a game-changer. It can be easily cut, drilled, and thermoformed with standard tools, providing a durable yet pliant solution that withstands the rigors of outdoor exposure and frequent handling. Truly, this combination of lightweight and flexibility makes acrylic sheet or plexiglass a prized material in South Africa’s diverse range of applications.

Cost-Effectiveness – Affordable alternative to glass

In a landscape where budget constraints often dictate design choices, acrylic sheet or plexiglass emerges as a beacon of affordability without sacrificing quality. Its cost-effectiveness is nothing short of revolutionary for South African projects—be it retail displays, architectural accents, or protective barriers. Unlike traditional glass, which can be prohibitively expensive and heavy, acrylic sheet or plexiglass offers a budget-friendly alternative that doesn’t compromise on durability or aesthetic appeal.

One of the most compelling benefits of acrylic sheet or plexiglass is its ability to deliver high performance at a fraction of the cost. This material is easy to source locally, reducing logistical expenses and lead times. Its affordability opens doors for small businesses and large-scale contractors alike, allowing for innovative designs that were previously constrained by financial limitations. For projects where visual clarity and structural integrity matter, acrylic sheet or plexiglass strikes an impressive balance between price and quality.

Furthermore, the versatility of acrylic sheet or plexiglass translates into significant savings in installation and maintenance. Its lightweight nature minimizes labor costs, while its resilience extends the lifespan of installations, reducing the need for frequent replacements. Whether used for signage, glazing, or decorative features, acrylic sheet or plexiglass stands out as an economical choice for those seeking durability and elegance without overstretching their budget.

Common Applications of Acrylic Sheets and Plexiglass

Architectural and Interior Design – Partitions, display cases, and decorative elements

In the realm of modern architecture and interior design, acrylic sheet or plexiglass has quietly become the unsung hero—an elegant solution that marries practicality with aesthetic appeal. With its remarkable optical clarity and versatility, acrylic sheet or plexiglass transforms everyday spaces into showcases of sophistication. From sleek partitions that subtly divide open-plan offices to eye-catching display cases that elevate merchandise, the applications are as diverse as they are ingenious.

Architects and designers frequently turn to acrylic sheet or plexiglass for decorative elements that demand both form and function. Its lightweight nature makes installation a breeze, while its durability ensures these features stand the test of time. For instance, in retail settings across South Africa, acrylic sheet or plexiglass is indispensable for creating transparent, impact-resistant display enclosures. Similarly, in upscale interiors, it lends itself beautifully to decorative panels, stair railings, and even bespoke lighting fixtures that shimmer with understated elegance.

In fact, the material’s adaptability extends beyond interior décor. Acrylic sheet or plexiglass is often used in outdoor fixtures, thanks to its weather and UV resistance. Whether as protective barriers for bustling cafés or vibrant signage that captures attention from afar, this material’s resilience ensures longevity and visual clarity—making it a staple in both commercial and residential projects.

Signage and Advertisement – Billboards, retail displays, and illuminated signs

Acrylic sheet or plexiglass has become a cornerstone in signage and advertising across South Africa. Its high optical clarity and versatility make it ideal for creating eye-catching billboards, retail displays, and illuminated signs. These materials offer a sleek, professional appearance that attracts attention from afar and up close alike.

In the world of outdoor advertising, acrylic sheet or plexiglass excels thanks to its weather and UV resistance. It withstands harsh sunlight and rain without yellowing or cracking, ensuring your message stays vibrant over time. Whether used for large-scale billboards or smaller promotional displays, it provides a durable, lightweight alternative to traditional signage materials.

- Billboards that command attention with crisp visuals

- Retail displays that showcase products with clarity and style

- Illuminated signs that shine brightly even in low light conditions

The adaptability of acrylic sheet or plexiglass extends into creative signage solutions. It can be custom-cut into various shapes and sizes, allowing for innovative branding and advertising concepts. Its ability to be backlit makes it perfect for illuminated signage that stands out in busy commercial districts or retail environments.

Lighting Fixtures – Lenses, diffusers, and decorative lighting

Beyond signage and advertising, acrylic sheet or plexiglass has carved out a niche in the realm of lighting solutions that blend functionality with artistry. Its optical clarity and versatility make it a preferred choice for crafting lenses, diffusers, and decorative lighting fixtures. When used as lenses, acrylic sheet or plexiglass can focus or disperse light with remarkable precision, transforming ordinary illumination into captivating visual experiences.

Diffusers made from acrylic provide a seamless way to soften harsh lighting, creating a warm, inviting ambiance in both residential and commercial spaces. The material’s ability to be thermoformed allows designers to shape intricate patterns and textures, elevating the aesthetic appeal of lighting installations. For decorative purposes, acrylic sheet or plexiglass lends itself beautifully to bespoke light fixtures, chandeliers, and artistic installations—each piece a testament to the material’s flexibility and durability.

- Custom-cut shapes for unique lighting designs

- Backlit panels that enhance retail displays or architectural features

- Decorative LED screens with sleek, modern appeal

In the South African context, where outdoor and indoor lighting needs often demand resilience and style, acrylic sheet or plexiglass stands out as an innovative solution. Its non-yellowing properties ensure that decorative lighting maintains its brilliance over time, even under intense sun exposure. Whether creating a statement piece in a high-end retail space or illuminating a cozy home interior, acrylic sheet or plexiglass offers endless creative possibilities that marry practicality with aesthetic elegance.

Industrial Uses – Machine guards, skylights, and protective barriers

In the vibrant landscape of South Africa’s architectural and industrial sectors, acrylic sheet or plexiglass continues to shine as a versatile marvel. Its resilience and clarity make it an ideal material for a variety of applications that demand both strength and finesse. From protective barriers that safeguard health and safety to skylights that bathe interiors in natural light, this material transforms ordinary spaces into extraordinary experiences.

Industrial uses of acrylic sheet or plexiglass are equally compelling. Machine guards crafted from this material provide a robust shield against hazards while maintaining visibility, ensuring safety without sacrificing operational efficiency. Skylights made from acrylic are prized for their ability to withstand harsh sun exposure, resisting yellowing and cracking over time. Protective barriers, whether in retail environments or industrial facilities, serve as transparent sentinels—creating a secure boundary that doesn’t compromise aesthetic appeal.

For those seeking to elevate their space with innovative design, acrylic sheet or plexiglass offers countless possibilities. Custom-cut shapes can be tailored to fit precise specifications, transforming functional barriers into works of art. As a testament to its adaptability, acrylic is often employed to produce:

- Elegant display cases that blend seamlessly into interior decor

- Intricate architectural partitions that define spaces with a touch of sophistication

- Modern protective screens that combine style with safety

In South Africa’s dynamic environment, where outdoor resilience is paramount, acrylic sheet or plexiglass stands out as an unparalleled choice. Its high impact resistance and weatherproof qualities make it suitable for both indoor and outdoor applications, ensuring longevity and visual integrity. Whether used to craft a striking retail storefront or a protective barrier in a bustling industrial site, acrylic sheet or plexiglass embodies the perfect union of practicality and aesthetic elegance, transforming everyday spaces into extraordinary visions of clarity and strength.

DIY and Craft Projects – Home improvement and creative uses

In the realm of DIY projects and home improvement, acrylic sheet or plexiglass emerges as a material of endless possibility. Its versatility transforms simple ideas into stunning creations, whether you’re crafting a custom photo frame or building a modern terrarium. Thanks to its lightweight yet durable nature, acrylic sheet or plexiglass is easy to cut, drill, and shape—making creative endeavors accessible for hobbyists and professionals alike.

From decorative accents to functional enhancements, the applications are virtually limitless. Many enthusiasts opt for acrylic sheet or plexiglass when designing unique lighting fixtures that cast beautiful diffused glow or when creating personalized signage that commands attention. Its optical clarity enhances visual appeal, ensuring every piece looks polished and professional. For those seeking to add a touch of sophistication to their living spaces, custom-cut acrylic can serve as elegant tabletops, protective covers, or even artistic wall panels.

For practical purposes, acrylic sheet or plexiglass can be used to make safety screens or protective barriers that maintain transparency while providing robust protection. Its weather resistance and impact durability also make it ideal for outdoor projects—think garden displays or weatherproof storage solutions. Whether you’re a seasoned craftsperson or a passionate beginner, acrylic sheet or plexiglass invites innovation, blending aesthetic appeal with practical resilience in every project.

Choosing the Right Acrylic Sheet or Plexiglass

Factors to Consider – Thickness, size, and color options

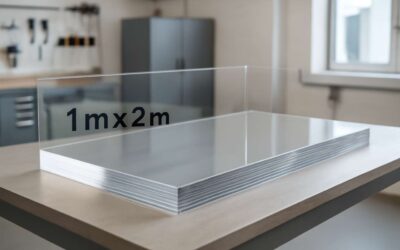

Choosing the right acrylic sheet or plexiglass can feel like navigating a labyrinth—each decision influencing the final outcome. One of the most critical factors is thickness; a thicker acrylic sheet or plexiglass offers enhanced durability and impact resistance, ideal for safeguarding valuable assets or creating sturdy partitions. Conversely, thinner variants provide flexibility and ease of installation, perfect for intricate craft projects or lightweight signage.

Size considerations are equally pivotal. Custom dimensions ensure seamless integration into your space, but understanding your specific application helps determine the optimal size—whether for large outdoor billboards or compact decorative panels. Color options further expand creative possibilities, from transparent clarity that maximizes light transmission to vibrant hues for eye-catching displays.

For outdoor applications, UV-resistant acrylic sheet or plexiglass is essential, ensuring longevity even under South Africa’s intense sunlight. When selecting, examine the specific properties of each variant, aligning them with your aesthetic and functional needs.

Performance Requirements – Impact, UV exposure, and thermal stability

In the realm of visionaries and craftsmen, selecting the perfect acrylic sheet or plexiglass is akin to composing a symphony—each note, or property, must harmonize with your project’s demands. When contemplating impact resistance, remember that a robust acrylic sheet or plexiglass acts as a steadfast guardian, shielding valuable assets with unwavering strength. For outdoor ventures, UV exposure becomes a relentless adversary, yet choosing a UV-resistant variant ensures your creation endures South Africa’s fiery sun without fading into obscurity. Thermal stability is another vital trait, especially in environments with fluctuating temperatures, preventing warping or cracking under stress.

To better grasp these vital criteria, consider this ordered list:

- Impact strength—how well the acrylic sheet or plexiglass withstands sudden shocks and blows.

- UV resistance—ensuring longevity and clarity amidst relentless sunlight.

- Thermal stability—maintaining structural integrity in varying climates.

By aligning these performance requirements with your specific application, you craft not just a functional piece but a resilient masterpiece. Whether for a sleek display case or a protective barrier, the right acrylic sheet or plexiglass transforms practicality into poetry, standing tall against time and elements alike.

Budget Constraints – Cost considerations and value

Choosing the right acrylic sheet or plexiglass often boils down to a delicate dance between your project’s aspirations and your budget’s gentle constraints. While affordability is enticing, it’s essential to weigh the long-term value that each variant offers. A cheaper acrylic sheet may seem like a wise investment initially, but if it lacks UV resistance or thermal stability, your masterpiece could fade or warp under South Africa’s fierce sun and fluctuating temperatures.

Opting for a higher-quality acrylic sheet or plexiglass with enhanced impact resistance and optical clarity can transform a simple structure into an enduring marvel. When selecting, consider the specific needs of your application—whether it’s a sleek display case or a durable outdoor barrier. Remember, the true magic lies in balancing cost with the performance traits that guarantee resilience and beauty over time. Sometimes, investing a little more ensures your creation stands resilient, shining brightly against the test of time.

Environmental Considerations – Recyclability and eco-friendly options

In a world increasingly conscious of environmental impact, selecting the right acrylic sheet or plexiglass isn’t just about durability or aesthetics—it’s about making a choice that aligns with eco-friendly values. South Africa’s abundant sunlight and warm climate demand materials that stand the test of time without harming our precious environment. Fortunately, many acrylic sheet or plexiglass options are now manufactured with recyclability in mind, reducing waste and conserving resources.

Opting for recycled acrylic or plexiglass can significantly lessen your project’s carbon footprint. These eco-friendly variants often come from post-consumer waste, giving new life to what might otherwise be discarded. When choosing, consider suppliers that prioritize sustainability and offer recyclable acrylic sheet or plexiglass options. This not only supports global efforts to reduce plastic waste but also ensures your project remains environmentally responsible.

Additionally, some manufacturers produce biodegradable or bio-based acrylic sheet or plexiglass, further enhancing eco-conscious choices. Incorporating these sustainable materials into your design can elevate your project’s impact, resonating with clients who value environmental stewardship. Ultimately, balancing performance with ecological considerations ensures your creations are both beautiful and kind to our planet.

Maintenance and Care for Acrylic Sheets and Plexiglass

Cleaning Tips – Proper cleaning agents and techniques

In the realm of acrylic sheet or plexiglass, maintaining their pristine appeal is an art as delicate as a brushstroke on glass. These materials, celebrated for their optical clarity and resilience, demand a gentle touch when it comes to cleaning and upkeep. Proper maintenance not only preserves their transparency but also extends their lifespan, ensuring they continue to dazzle in any setting, from architectural marvels to retail displays.

When it comes to cleaning acrylic sheet or plexiglass, the choice of cleaning agents is crucial. Harsh chemicals, like ammonia-based cleaners or abrasive scrubbers, can cause micro-scratches or clouding, diminishing their brilliance. Instead, opt for a mild dish soap mixed with warm water or a specialized acrylic cleaner. Use a soft, lint-free cloth or a microfiber towel to gently wipe the surface in a circular motion, avoiding excessive pressure that might cause damage.

For routine upkeep, consider a simple cleaning routine:

- Spray the surface with a gentle cleaner or soapy solution.

- Wipe with a soft cloth, ensuring no streaks or residue remain.

- Dry with a clean, dry microfiber cloth to prevent water spots.

Remember, never use rough sponges or scouring pads, as these can permanently scratch the delicate surface of acrylic sheet or plexiglass. Regular care, combined with proper cleaning techniques, keeps these versatile materials looking their best, whether installed outdoors or within elegant interiors. After all, the true magic of acrylic lies in its transparency—treat it kindly, and it will continue to reflect light beautifully for years to come!

Scratch Prevention – Handling and protective coatings

In the delicate dance of maintaining acrylic sheet or plexiglass, proper handling transforms routine care into an art form. These materials, renowned for their optical clarity and resilience, demand a gentle touch—like a whisper guiding a fragile masterpiece. Scratches and micro-abrasions are silent enemies, marring the surface and robbing it of its luminous allure. To prevent such damage, it is essential to adopt protective measures that preserve their pristine appearance over time.

One effective strategy involves applying a specialized protective coating designed explicitly for acrylic sheet or plexiglass. These coatings act as invisible shields—absorbing minor impacts and resisting scratches—without compromising transparency. Moreover, careful handling techniques, such as avoiding rough objects and using soft cloths, significantly reduce the risk of surface abrasions. When cleaning, always opt for non-abrasive tools and gentle cleaning agents, ensuring the material’s longevity and brilliance remain intact.

For added peace of mind, consider implementing a regular inspection routine. Check for signs of wear or minor scratches and address them promptly with appropriate polishing compounds. Remember, safeguarding acrylic sheet or plexiglass isn’t merely about aesthetics; it’s about extending the lifespan of these versatile materials so they continue to reflect light with unblemished clarity, whether used in architectural marvels or retail displays.

- Use soft, lint-free cloths to handle and clean the surface

- Apply protective coatings formulated for acrylic and plexiglass

- Avoid placing sharp or abrasive objects near the material

- Perform routine inspections to identify and address surface damage early

Embracing these practices ensures that the brilliance of acrylic sheet or plexiglass endures, shining brightly amidst the demands of daily use and environmental challenges. The secret lies in the careful stewardship of these luminous materials—treat them with respect, and they will continue to captivate with their clarity for years to come.

Care to Avoid Damage – Installation tips and usage warnings

Maintaining the pristine allure of acrylic sheet or plexiglass isn’t just about occasional cleaning; it’s an ongoing act of devotion. These materials, celebrated for their optical clarity and versatility, require careful handling to avoid damage that can turn their luminous shine into a dull, scratched mess. Proper installation plays a crucial role—make sure the acrylic sheet or plexiglass is secured with gentle, non-abrasive fittings to prevent undue stress or cracks. Sharp objects or rough handling during setup? Avoid them like the plague! A little caution during installation can save hours of cleaning and polishing later.

Routine care involves more than just wiping down surfaces. Regular inspections are vital to catch micro-abrasions before they turn into unsightly scratches. When cleaning, always use soft, lint-free cloths and gentle, non-abrasive cleaning agents tailored for acrylic or plexiglass. Harsh chemicals or abrasive scrubbers are the enemies of clarity and should be banished from your cleaning arsenal. To further safeguard your investment, consider applying a protective coating formulated specifically for acrylic sheet or plexiglass—these invisible shields add an extra layer of defense against scratches and impacts.

In the world of acrylic sheet or plexiglass, the mantra is: less is more when it comes to contact. Keep sharp or abrasive objects at bay and avoid placing heavy or rough items directly on these surfaces. When in doubt, opt for a soft cloth and a gentle touch—your acrylic’s brightness depends on it! Remember, a proactive approach to maintenance not only preserves the aesthetic appeal but also prolongs the lifespan of these versatile materials, ensuring they continue to impress whether used in retail displays, architectural features, or industrial applications.

Repairing Scratches and Damage – DIY fixes and when to seek professional help

Maintaining the luminous integrity of acrylic sheet or plexiglass is a nuanced dance—one that demands vigilance and patience. These materials, prized for their optical clarity and resilience, are surprisingly delicate when it comes to scratches or cracks. A small blemish can transform their once-glossy surface into a dull, marred landscape, diminishing their visual appeal and structural integrity. Regular inspections are essential, not just to spot visible damage but to catch micro-abrasions lurking beneath the surface, which can escalate if left unchecked.

When it comes to repairing scratches and damage on acrylic sheet or plexiglass, the approach must be deliberate. For minor scratches, a gentle polishing compound designed for acrylic can restore clarity—applied with a soft cloth in circular motions. However, deeper gouges or cracks often require more sophisticated intervention. In such cases, DIY fixes like acrylic repair kits may suffice temporarily, but—trust me—knowing when to seek professional help is crucial. Professionals can employ specialized tools and techniques, such as thermal bonding or precision sanding, which preserve the optical properties and structural integrity of the material without risking further damage.

Careful handling during installation and routine cleaning plays a vital role in safeguarding these delicate yet durable materials. Remember, abrasive scrubbers or harsh chemicals are the arch-nemeses of acrylic sheet or plexiglass, capable of causing irreversible damage. Instead, opt for a gentle touch—using soft, lint-free cloths and approved cleaning solutions to remove dirt and smudges. And for those seeking extra protection, applying a high-quality, transparent protective coating can act as an invisible shield, guarding against scratches and impacts over time.

Ultimately, understanding the delicate balance between maintenance and repair underpins the longevity of acrylic sheet or plexiglass. Whether in architectural marvels, retail displays, or industrial environments, these materials demand a nuanced approach—one that combines vigilance, gentle handling, and expert intervention when necessary. When approached with care, the luminous allure of acrylic sheet or plexiglass can be preserved for decades, continuing to impress with their pristine elegance and versatile performance.

Purchasing and Sourcing Acrylic Sheet or Plexiglass

Where to Buy – Online retailers, local distributors, and specialty stores

Looking to get your hands on some top-notch acrylic sheet or plexiglass? The good news is, sourcing this versatile material is easier than finding a South African braai grill on a Sunday afternoon! Whether you prefer the convenience of online retailers, local distributors, or specialty stores, there’s a procurement option tailored to your needs.

Online retailers offer a vast array of acrylic sheet or plexiglass, often at competitive prices and with the benefit of doorstep delivery. This is perfect for those who value time and want to avoid traffic jams in the city. Local distributors, on the other hand, provide the advantage of immediate inspection and hands-on assistance. If you’re after tailored sizes or custom cuts, specialty stores usually have the expertise to meet your specifications with precision.

For the savvy buyer, a mix-and-match approach often yields the best results. Consider ordering standard sheets online for bulk projects, while visiting local outlets for specialty finishes or quick pick-ups. So, whether you’re crafting a stunning signage display or a durable DIY project, sourcing your acrylic sheet or plexiglass has never been more accessible and straightforward.

What to Look for in a Supplier – Quality certifications, customer reviews, and product options

When sourcing acrylic sheet or plexiglass, choosing the right supplier can make all the difference between a project that dazzles and one that disappoints. It’s not just about price—although, let’s be honest, who doesn’t love a bargain?—but about quality, reliability, and variety. Look for suppliers with solid **quality certifications**; these are your assurance that the acrylic sheet or plexiglass meets industry standards and will stand the test of time.

Customer reviews are another invaluable resource—think of them as the social proof that helps you avoid shady dealings and subpar materials. A reputable supplier will also offer a broad spectrum of **product options**—from various thicknesses and sizes to different finishes and colors—so you can find exactly what your project demands.

Remember, the best suppliers are those that understand the importance of transparency and support. Whether you’re after an impact-resistant acrylic sheet or UV-stabilized plexiglass for outdoor signage, a trustworthy vendor will have the expertise to guide you through the selection process, ensuring your investment is well spent.

Custom Cutting and Fabrication Services – Options for tailored sizes and shapes

When embarking on a project that demands precision and finesse, sourcing the right acrylic sheet or plexiglass is only half the journey. The other half lies in selecting a vendor that offers custom cutting and fabrication services tailored to your unique needs. Imagine a master artisan shaping a block of crystal-clear material into a bespoke piece—this is the essence of custom fabrication. Whether you require intricate curves, precise holes, or specific dimensions, reputable suppliers can transform standard sheets into precisely what your project demands.

Opting for tailored sizes and shapes isn’t merely about aesthetics; it ensures optimal material efficiency and reduces waste, ultimately saving costs. Many providers offer custom cutting services that can produce everything from thin, delicate panels to robust, impact-resistant shields. For added convenience, some suppliers provide a variety of finishes—such as matte, gloss, or textured—to complement your design vision. These options make it possible to craft everything from elegant signage to durable industrial barriers with ease and confidence.

In the realm of acrylic sheet or plexiglass, the ability to source custom-fabricated pieces is akin to wielding a magic wand—transforming raw material into a masterpiece that aligns perfectly with your project’s specifications. This bespoke approach empowers designers, architects, and DIY enthusiasts alike to push the boundaries of creativity and functionality, ensuring every element fits seamlessly into the grand tapestry of their vision.

Pricing and Lead Times – Cost estimates and delivery considerations

Purchasing and sourcing acrylic sheet or plexiglass involves more than just selecting the right thickness or color; it requires a keen eye on cost estimates and delivery timelines that align with your project’s demands. The global market for acrylic sheet or plexiglass has seen fluctuations driven by raw material costs and manufacturing complexities, impacting overall pricing. Typically, prices can vary based on the type of acrylic—cast or extruded—as well as the size and finish options selected.

Lead times are equally crucial, especially when deadlines are tight. Reputable suppliers often provide estimates ranging from a few days for standard sheets to several weeks for custom-fabricated pieces. To help streamline your decision-making process, consider this simplified overview:

- Request detailed quotes that specify material type, thickness, and finish options.

- Confirm lead times upfront to avoid delays in your project schedule.

- Inquire about bulk discounts if ordering multiple sheets for large-scale applications.

Understanding these factors ensures that your purchase of acrylic sheet or plexiglass not only meets your technical specifications but also stays within your budget. Whether sourcing locally in South Africa or exploring international suppliers, transparency in pricing and delivery is key to a successful project.

Environmental Impact and Sustainability

Recyclability of Acrylic and Plexiglass – Recycling processes and programs

In a world increasingly conscious of environmental footprints, the sustainability of acrylic sheet or plexiglass emerges as a compelling consideration. These materials can be recycled repeatedly without significant degradation, reducing waste and conserving resources. Recycling programs for acrylic and plexiglass often involve collection, cleaning, and reprocessing into new sheets—an eco-friendly cycle that minimizes landfill contributions. Interestingly, many manufacturers now prioritize closed-loop recycling, ensuring that scrap or used acrylic sheet or plexiglass is reincarnated into pristine, usable products.

Moreover, the recyclability of acrylic sheet or plexiglass aligns with global efforts to promote a circular economy. While some may perceive plastics as inherently detrimental, modern recycling processes challenge that notion—transforming what was once waste into valuable raw material. This shift not only lessens the environmental impact but also encourages responsible consumption. In South Africa, such initiatives are gaining momentum, emphasizing that sustainability is achievable without sacrificing quality or innovation. It’s a testament to the material’s adaptability and the industry’s commitment to eco-conscious manufacturing.

Fundamentally, embracing recyclable acrylic sheet or plexiglass isn’t just about environmental responsibility; it’s about forging a future where durability meets ecological integrity. The ongoing development of advanced recycling techniques underscores a vital truth: our choices today shape the sustainability of tomorrow’s environment. By integrating these practices, we can enjoy the benefits of acrylic sheet or plexiglass while respecting the planet’s delicate balance.

Environmental Benefits – Potential for reducing energy use and material waste

In the shadowed corridors of sustainability, acrylic sheet or plexiglass emerges as a beacon of hope—a material that whispers promises of environmental redemption. Its unique capacity for recyclability transforms waste into a resource, breathing new life into what was once destined for the landfill. Each recycled sheet echoes a commitment to reducing material waste, a crucial step in forging a more responsible future.

Modern recycling processes for acrylic and plexiglass are a symphony of precision—collection, cleansing, and reprocessing—culminating in pristine sheets that rival their original counterparts. Such eco-friendly cycles not only diminish landfill contributions but also bolster efforts towards a circular economy. For South Africa, where environmental concerns grow more urgent with each passing day, these initiatives are more than just industry trends—they are vital movements towards sustainability.

Leveraging the potential of acrylic sheet or plexiglass can significantly reduce energy use across manufacturing and installation phases. Because these materials are lightweight and flexible, they demand less energy during transportation and handling, creating a cascade of ecological benefits. Additionally, their durability means fewer replacements, minimizing waste and conserving natural resources. When combined with advanced recycling techniques, acrylic and plexiglass stand as testament to sustainable innovation—proof that beauty and responsibility can coexist in harmony.

Innovations in Eco-Friendly Alternatives – Biodegradable and sustainable options

In a world increasingly attuned to ecological harmony, the quest for sustainable materials takes center stage. Acrylic sheet or plexiglass, once celebrated solely for their optical clarity and durability, now shine brighter as symbols of environmental innovation. These materials are pioneering pathways toward eco-friendly alternatives, blending beauty with responsibility in remarkable ways.

Recent advancements have paved the way for biodegradable and sustainable options for acrylic sheet or plexiglass. Researchers are developing formulations that incorporate bio-based resins and natural additives, aiming to reduce their carbon footprint. Such innovations not only diminish reliance on fossil fuels but also foster a circular economy—where waste is transformed into a resource rather than discarded as trash. For example, some manufacturers now offer recycled acrylic sheets, which undergo meticulous reprocessing to produce pristine, impact-resistant panels that rival new material in performance.

Embracing eco-conscious manufacturing processes, the industry is harnessing cleaner energy sources and refining recycling techniques. This shift significantly reduces greenhouse gas emissions and minimizes environmental impact. For those committed to sustainability, acrylic sheet or plexiglass presents an alluring alternative—combining transparency, resilience, and a lighter ecological footprint. As South Africa’s environmental concerns intensify, these innovations stand as testament to the power of creative sustainability, turning what was once waste into a vital resource.

0 Comments