Understanding 3M Perspex Sheet

What is 3M Perspex Sheet? – Overview and definition of 3M Perspex sheet

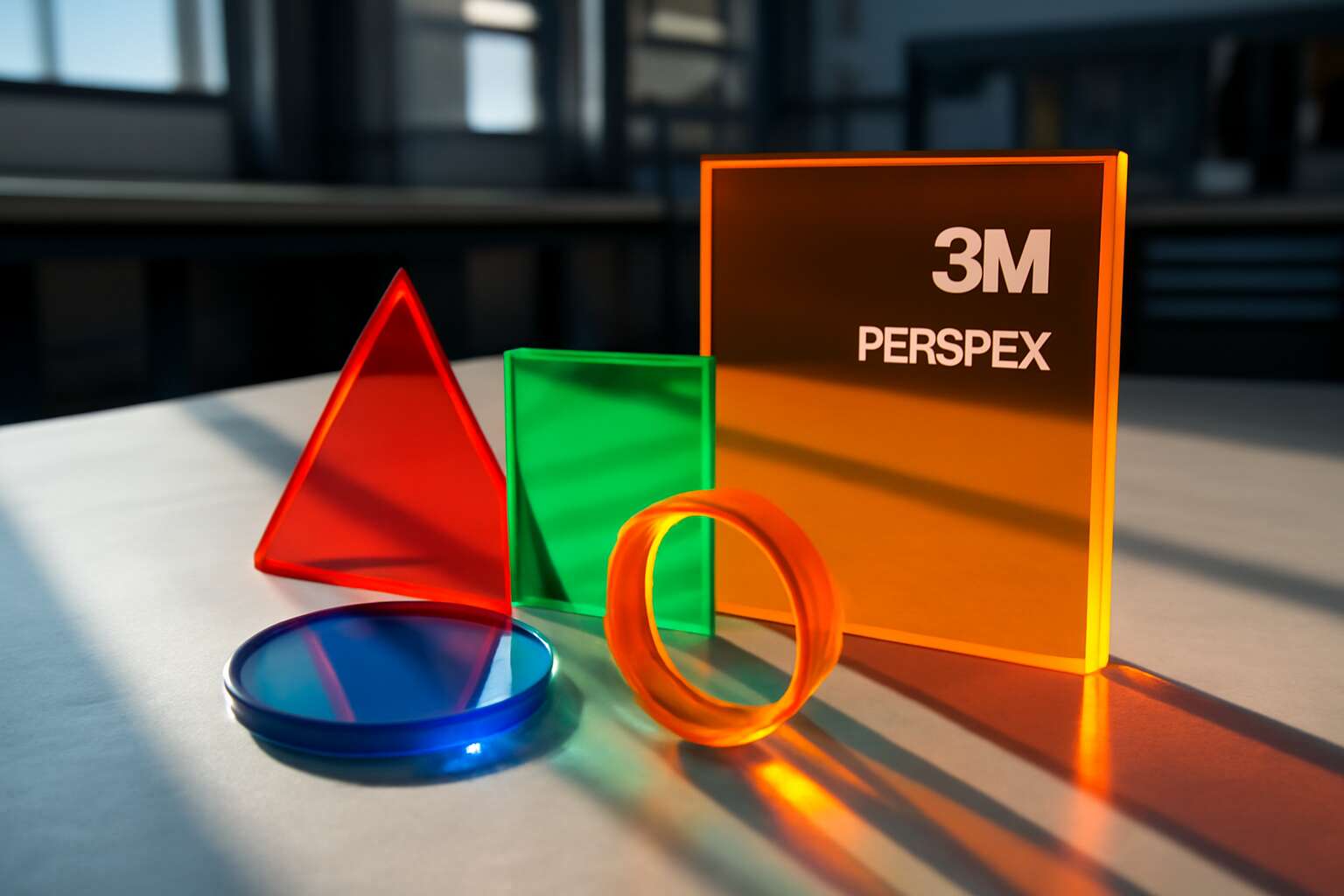

In the realm of modern manufacturing and design, 3M Perspex sheet stands out as a versatile and durable material. Known for its clarity and resilience, this acrylic sheet offers a high-quality alternative to glass, combining lightweight properties with exceptional strength. Its popularity continues to grow across various industries in South Africa, from signage to retail displays.

What exactly is a 3M Perspex sheet? Essentially, it’s a specially manufactured acrylic sheet produced by 3M, renowned for their innovation and quality. The sheet provides an impressive balance of transparency and toughness, making it suitable for both interior and exterior applications. Thanks to advanced manufacturing techniques, 3M Perspex sheets boast UV resistance, ensuring they maintain their clarity over time even under harsh sunlight.

For those seeking specific features, here are some key benefits of a 3M Perspex sheet:

- High optical clarity for unobstructed visibility

- Impact resistance superior to traditional glass

- Ease of fabrication, cutting, and installation

Whether used for decorative purposes or safety barriers, the 3M perspex sheet offers a reliable, cost-effective solution. Its adaptability makes it a staple choice for South African businesses aiming for quality and longevity in their projects.

Key Features and Benefits – Durability, clarity, UV resistance, and ease of installation

In the world of modern construction and design, few materials command the same level of admiration as the 3M perspex sheet. Its resilience and clarity are nothing short of impressive, transforming ordinary spaces into extraordinary showcases. But what truly elevates this acrylic marvel from mere plastic to a trusted industry staple is its suite of key features and benefits.

First and foremost, durability is at the heart of the 3M perspex sheet. Unlike glass, which can shatter at the slightest impact, this acrylic alternative offers superior impact resistance, making it an ideal choice for high-traffic areas or safety barriers. Its robust nature ensures longevity, standing firm against the rigours of daily use in South African environments.

Clarity is another defining characteristic. The 3M perspex sheet provides high optical transparency, allowing for unobstructed views that enhance aesthetics and functionality. Whether used in retail displays or decorative installations, its ability to transmit light seamlessly makes it a preferred choice among designers and architects alike.

Furthermore, UV resistance plays a critical role in maintaining appearance and performance over time. Thanks to advanced manufacturing techniques, the 3M perspex sheet resists yellowing and degradation from harsh sunlight, a common challenge in South Africa’s sunny climate. This ensures your investment remains pristine and vibrant for years to come.

Ease of installation and fabrication is the cherry on top. The 3M perspex sheet can be cut, drilled, and shaped with relative ease, reducing installation time and costs. For those involved in custom projects or quick turnaround requirements, this feature is nothing short of a blessing.

- Exceptional impact resistance

- High optical clarity for unobstructed visibility

- UV resistance to withstand harsh sunlight

- Simple fabrication and installation process

In essence, the 3M perspex sheet embodies a perfect blend of resilience, aesthetic appeal, and practicality—making it an indispensable material for modern South African enterprises. Its multifaceted benefits ensure that whether you’re creating a safety barrier or adding a touch of elegance, this acrylic sheet will never let you down.

Different Types and Grades – Acrylic, polycarbonate, and specialty variants

When navigating the vibrant landscape of construction and design, understanding the different types and grades of the 3M perspex sheet is crucial. Not all acrylics are created equal, and selecting the right variant can make or break your project. From the crystal-clear elegance of acrylic to the bulletproof bravado of polycarbonate, the choices are as diverse as South Africa’s landscapes.

For those seeking a balance between affordability and durability, the standard acrylic 3M perspex sheet is a popular pick. It offers excellent optical clarity and impact resistance, making it perfect for retail displays and decorative panels. But if your project demands something more resilient—say, a safety barrier in a high-traffic area—you might want to consider polycarbonate variants. These are tougher than a rhino’s hide and provide superior impact strength, though at a slightly higher price point.

Moreover, there are specialty variants of the 3M perspex sheet, crafted for specific needs like UV stability or flame retardancy. These variants are engineered to withstand South Africa’s intense sunlight and unpredictable climate with aplomb. Whether it’s a high-performance sheet for a commercial installation or a decorative piece that needs to stay pristine over the years, the right grade can elevate your project from ordinary to extraordinary.

- Standard acrylic for everyday clarity and impact resistance

- Polycarbonate for maximum toughness and safety

- Specialty variants for UV resistance, flame retardancy, or other unique requirements

Choosing the appropriate 3M perspex sheet grade isn’t just about technical specs—it’s about matching the material’s strengths to your project’s specific demands. With a spectrum of options available, you can confidently craft solutions that stand tall against South Africa’s sun and hustle while maintaining an elegant aesthetic. Because when it comes to 3M perspex sheet, versatility is just the beginning!

Applications of 3M Perspex Sheet

Commercial Uses – Display cases, signage, and retail fixtures

In the world of commercial design, 3M Perspex sheet is transforming the way businesses showcase their brands. Its versatility makes it a preferred choice for display cases, signage, and retail fixtures. Stores and exhibitions rely on 3M Perspex sheet to create eye-catching visuals that stand out and last. The clarity and durability of this material ensure that products are displayed vividly and securely, even in high-traffic environments.

From illuminated signs to sleek retail counters, 3M Perspex sheet offers a professional finish that elevates any commercial space. Its resistance to UV rays prevents yellowing over time, maintaining a crisp appearance for years. For signage, the ease of fabrication and installation means quick turnaround times without sacrificing quality. Whether used for custom display cases or branded signage, this material’s adaptability proves invaluable in retail and corporate settings.

Here are some typical applications of 3M Perspex sheet in commercial use:

- Display cases that highlight products while protecting them from dust and damage

- Signage that commands attention both indoors and outdoors

- Retail fixtures that combine style with practicality, such as shelving and counters

In relation to retail fixtures, the smooth surface of 3M Perspex sheet simplifies cleaning and maintenance, ensuring the space remains pristine. Its range of finishes and thicknesses allows for tailored solutions that meet specific design needs. When considering a durable, high-quality material for your commercial project, 3M Perspex sheet is a reliable choice that delivers both form and function.

Industrial Applications – Safety barriers, machinery covers, and protective shields

In industrial settings across South Africa, safety is paramount—and 3M Perspex sheet stands as a cornerstone in creating secure, effective solutions. Its exceptional strength and transparency make it ideal for constructing safety barriers that not only protect personnel but also maintain visibility in busy environments. When used as machinery covers, 3M Perspex sheet shields operators from moving parts and debris, reducing the risk of accidents while keeping operational insights clear.

Protective shields made from 3M Perspex sheet serve as a vital line of defense against potential hazards, especially in manufacturing and industrial facilities. The versatility of this material allows it to be fabricated into custom shapes and sizes, fitting seamlessly into existing safety protocols. Its resistance to impact and UV degradation ensures long-lasting performance, even under rigorous conditions.

- Safety barriers that delineate work zones without obstructing airflow or visibility

- Machinery covers that shield operators from moving parts and electrical components

- Protective shields designed for high-traffic areas, minimizing injury risks

With manufacturing environments constantly evolving, the application of 3M Perspex sheet in safety equipment exemplifies a blend of practicality and innovation. Its capacity to withstand impact and weathering challenges makes it indispensable for safeguarding workers and equipment alike. The material’s clarity ensures that safety measures do not compromise operational efficiency, a vital consideration in busy South African industries where safety and productivity must coexist seamlessly.

Home and DIY Projects – Decorative panels, furniture, and light diffusers

In the shadowed corners of home and workshop, where artistry meets utility, 3M Perspex sheet emerges as a silent muse. Its crystalline clarity transforms mundane surfaces into delicate displays of craftsmanship, inviting admiration beneath the dim glow of ambient light. For those who seek to craft luminous accents or subtle partitions, this material offers an ethereal quality that elevates any space.

Decorative panels fashioned from 3M Perspex sheet breathe life into dull walls, casting a spell of sophistication and intrigue. Its versatility lends itself effortlessly to bespoke furniture — think sleek tabletops or elegant shelving that withstand the test of time. Light diffusers made from this material soften harsh beams, creating an ambiance as haunting as a moonlit night, perfect for both cozy homes and artistic studios.

For the DIY enthusiast, the possibilities are endless. With a few simple tools, 3M Perspex sheet can be carved, drilled, or shaped to fit any vision. From intricate light fixtures to personalized room dividers, this material transforms creative ideas into tangible realities. Its seamless blend of durability and translucence makes it an ideal choice for those who wish to merge functionality with a touch of gothic elegance.

Advantages of Choosing 3M Perspex Sheet

Enhanced Durability and Impact Resistance – Long-lasting and shatter-resistant features

When durability meets resilience, 3M Perspex sheet stands out as a stellar choice for both commercial and residential applications. Its enhanced impact resistance means it can withstand the rough and tumble of everyday life—whether it’s a busy retail environment or a bustling home workshop. This material isn’t just about looking good; it’s about enduring the test of time, even in the most demanding settings.

The impact resistance of 3M Perspex sheet is truly remarkable. Unlike traditional glass, which can shatter into dangerous shards, the 3m perspex sheet remains intact, offering a safer alternative. This shatter-resistant feature is invaluable in environments where safety is paramount, such as in schools, clinics, or public spaces. Its long-lasting nature ensures that investments in signage or protective barriers don’t need frequent replacing, saving both money and effort in the long run.

For those seeking a combination of strength and longevity, the 3m perspex sheet provides an ideal solution. Its robust construction means it resists scratches and impacts, maintaining clarity and appearance over years of use. This resilience makes it suitable for a wide range of applications—from protective shields in industrial settings to decorative panels in homes—highlighting its versatility and reliability in every scenario. Truly, choosing a 3m perspex sheet means embracing a durable, impact-resistant future that stands the test of time!

Optical Clarity and Aesthetic Appeal – High transparency for visual applications

The allure of a 3M Perspex sheet lies not only in its remarkable transparency but also in its capacity to transform visual environments into captivating showcases. With high optical clarity, this material offers an unobstructed view—making it the preferred choice for applications where visual fidelity is paramount. Whether used in retail displays or architectural accents, the 3M Perspex sheet elevates aesthetics by providing a pristine, glass-like appearance that remains consistently vivid over time.

Its natural luminance and smooth surface ensure that light passes through with minimal distortion, creating an inviting and sophisticated ambiance. This clarity enhances the effectiveness of signage, art installations, and decorative panels, allowing visuals to truly pop. Moreover, the aesthetic appeal of the 3M Perspex sheet is complemented by its versatility—available in various finishes and colors to match any design vision.

For those seeking to marry beauty with practicality, the 3M Perspex sheet offers a compelling solution. Its ability to maintain transparency without yellowing or clouding under UV exposure guarantees that visual integrity endures, even in challenging environments. This enduring clarity makes it an essential component in high-end interiors and commercial projects where impeccable presentation is non-negotiable.

UV and Weather Resistance – Suitable for outdoor use and UV protection

When it comes to outdoor applications, the resilience of a 3M Perspex sheet truly shines. Its exceptional UV and weather resistance make it an ideal choice for South African environments, where sun and rain are relentless critics. Unlike lesser plastics that yellow, crack, or degrade under harsh conditions, the 3M Perspex sheet maintains its pristine clarity and structural integrity over time. This enduring durability ensures your investment remains visually striking and functional, whether in signage, outdoor displays, or architectural accents.

Moreover, the UV protection inherent in the 3M Perspex sheet shields your displays from the ravages of ultraviolet rays. This means vibrant colors stay vivid, and transparency remains unblemished, even after prolonged exposure. For those seeking an elegant yet practical solution that withstands the elements, the 3M Perspex sheet offers peace of mind and unmatched longevity. Its resistance to weathering cements its reputation as a premier material for outdoor signage, protective barriers, and decorative features that demand both beauty and resilience. Truly, choosing a 3M Perspex sheet is a decision that marries aesthetic appeal with practical endurance—ready to face South Africa’s climate head-on.

Ease of Fabrication and Maintenance – Cutting, polishing, and cleaning

When it comes to harnessing the true potential of 3M Perspex sheet, ease of fabrication and maintenance stands as a shining testament to its versatile appeal. This material is not only durable and visually striking but also remarkably user-friendly, making it a preferred choice for professionals and DIY enthusiasts alike. The ability to cut, shape, and polish a 3M Perspex sheet with relative ease transforms complex projects into achievable endeavors, even for those newer to working with acrylics.

Unlike other plastics that demand specialized tools and painstaking techniques, the 3M Perspex sheet responds beautifully to standard fabrication methods. Whether you’re creating intricate signage or custom furniture pieces, its forgiving nature ensures clean edges and smooth finishes. Cleaning and maintaining the sheet is equally straightforward; a simple wipe with a non-abrasive cloth and mild detergent restores its crystal-clear transparency, keeping your installation looking pristine for years to come.

- Cutting: The 3M Perspex sheet can be easily cut using saws designed for plastics, allowing for precise dimensions without cracking or chipping.

- Polishing: Minor scratches and edges can be effortlessly polished to restore that flawless, glass-like appearance.

- Cleaning: Regular maintenance involves gentle cleaning with non-abrasive cleaners, ensuring the sheet’s optical clarity remains unblemished.

This seamless blend of ease and elegance in fabrication and maintenance elevates the 3M Perspex sheet beyond mere plastic, transforming it into a canvas for creative expression. Its adaptability makes it an unrivaled choice for projects that demand both aesthetic appeal and practical resilience—truly, a material that stands ready to meet the demands of South Africa’s vibrant and ever-evolving landscape.

How to Select the Right 3M Perspex Sheet

Factors to Consider – Thickness, size, color, and type

Choosing the right 3M Perspex sheet involves more than just picking a size. With so many options available, understanding key factors like thickness, size, color, and type is essential to ensure your project’s success.

Thickness determines the strength and suitability for different applications. A thicker 3M Perspex sheet offers enhanced impact resistance, making it ideal for safety barriers or protective shields. Size matters too, especially when working on large signage or display cases; measuring accurately prevents wastage and ensures a perfect fit.

Color choices can influence aesthetic appeal and functionality. Clear options maximize optical clarity, while tinted variants add privacy or visual interest. The type of 3M Perspex sheet—whether acrylic, polycarbonate, or specialty variants—also impacts durability and use case.

When selecting, consider these factors carefully, as they directly influence performance and longevity. Whether for industrial, commercial, or home use, understanding these variables will help you choose the perfect 3M Perspex sheet for your needs.

Matching Specifications to Applications – Choosing the appropriate grade for your project

Choosing the right 3M Perspex sheet tailored to your specific application can mean the difference between a project that endures and one that falls apart. With a wide array of grades, thicknesses, and finishes available, matching the specifications to your needs is crucial.

For example, if you’re working on outdoor signage, opt for a 3M Perspex sheet with UV and weather resistance. Conversely, for indoor display cases, a high-clarity acrylic variant might be more appropriate. To simplify decision-making, consider creating a quick comparison chart that aligns your project’s demands with the sheet’s features.

In some cases, it’s beneficial to prioritize impact resistance over aesthetic appeal, especially in industrial environments. An ordered list can help clarify your choices:

- Assess environmental exposure (indoor vs outdoor)

- Determine required impact resistance

- Match color and transparency needs

- Choose the appropriate thickness for strength

Matching these specifications ensures your 3M Perspex sheet performs reliably and lasts longer, making your investment worthwhile.

Cost and Budget Considerations – Affordable options versus premium variants

Choosing the right 3M Perspex sheet isn’t just about matching specifications; it’s a strategic decision that can significantly impact your budget and project longevity. Costs can vary widely depending on the grade, thickness, and finish you select. While an affordable 3M Perspex sheet offers excellent value for simple indoor applications, opting for premium variants might be necessary for demanding outdoor or industrial environments where durability is paramount.

If budget constraints are tight, consider standard acrylic sheets that provide clarity and impact resistance at a lower price point. However, for projects requiring enhanced UV resistance or higher impact durability, investing in specialized grades can save money in the long run by reducing replacement frequency. An easy way to weigh options is to think about the project’s primary environment and performance needs, then align these with the sheet’s features. A well-chosen 3M Perspex sheet balances cost effectiveness with long-lasting performance, ensuring your investment remains resilient through time.

Installation and Maintenance of 3M Perspex Sheet

Installation Tips – Proper handling, cutting, and fixing techniques

Handling a 3M Perspex sheet with the finesse of a jeweller is essential to ensure its pristine appearance and longevity. Proper handling begins with clean, dry hands or the use of gloves to prevent fingerprints and smudges. When it comes to cutting, a fine-tooth saw or a laser cutter is your best friend—always ensure the blade is sharp to achieve smooth edges and avoid stress fractures. Fixing techniques should prioritize gentle but secure attachment methods; using appropriate adhesives designed specifically for acrylic or polycarbonate ensures a seamless finish without cracking.

For those venturing into installation, here are some tips to keep in mind:

- Use masking tape along the cut lines to prevent splintering and make precise cuts.

- Ensure the surface where the 3M perspex sheet will be mounted is clean, dry, and free of debris to promote adhesion and stability.

- Allow for expansion gaps if installing in outdoor or temperature-variable environments—this will prevent warping or buckling over time.

Maintaining your 3M perspex sheet post-installation involves regular cleaning with a soft cloth and a mild, non-abrasive cleaner. Avoid harsh chemicals that could degrade the material’s optical clarity or UV resistance, especially if the sheet is positioned outdoors. With a touch of care and attention to detail, your 3M perspex sheet can remain a stunning feature for years to come—standing true to its promise of durability and aesthetic appeal.

Cleaning and Care – Best practices to preserve clarity and prevent scratches

Preserving the pristine clarity of your 3M Perspex sheet is an art as delicate as it is vital. Regular cleaning with a soft cloth and a mild, non-abrasive cleaner ensures that optical brilliance remains untainted by the dust and grime of everyday life. Harsh chemicals, which can dull or cloud the surface, should be avoided at all costs—especially in outdoor applications where UV resistance is paramount.

To prevent scratches, always handle your 3M Perspex sheet with care, avoiding abrasive materials that could mar its surface. When cleaning, gently wipe in the direction of the grain, and consider using specialized acrylic cleaners for optimal results. For more stubborn stains or fingerprints, a mixture of warm water and a tiny drop of dish soap can work wonders without compromising the sheet’s durability.

For installation, masking tape along cut lines can be a lifesaver, reducing splintering and ensuring precise, clean edges. Remember, a pristine 3M Perspex sheet not only enhances aesthetic appeal but also prolongs its lifespan. Regular maintenance, coupled with mindful handling, transforms this versatile material into a lasting feature—glowing with clarity and resilience for years to come.

Troubleshooting Common Issues – Dealing with scratches, fogging, or discoloration

Every industrious Cape Town artisan or passionate DIY enthusiast knows the frustration of dealing with scratches, fogging, or discoloration on their 3M Perspex sheet. These issues, although common, can diminish the visual appeal and functionality of your project if not addressed promptly. Troubleshooting these problems requires a careful eye and a gentle touch—after all, preserving the optical clarity of your 3M Perspex sheet is vital for both aesthetic and safety reasons.

When scratches appear, it’s tempting to reach for abrasive cleaners, but this can make matters worse. Instead, use a fine polishing compound designed for acrylic surfaces, gently buffing the affected area. Fogging often results from moisture buildup or surface contamination; a soft cloth dampened with warm water mixed with a small amount of dish soap can help clear this up without damaging the sheet. If discoloration occurs, it may be due to prolonged UV exposure or chemical reactions—consider applying a UV-resistant coating or replacing the affected section if necessary.

To tackle persistent issues, try this simple approach:

- Identify the root cause—scratches, fogging, or discoloration.

- Choose appropriate cleaning or repair methods specific to the problem.

- Apply gentle techniques, avoiding harsh chemicals or abrasive tools.

- Regular maintenance can prevent future issues, prolonging the lifespan of your 3M Perspex sheet.

For surfaces with deep scratches, professional polishing might be the best route, ensuring the clarity and integrity of your acrylic sheet remain intact. Remember, handling your 3M Perspex sheet with care—especially during installation and cleaning—can make all the difference in maintaining its pristine appearance for years to come. Every scratch or foggy patch is a reminder to treat this versatile material with the respect it deserves, so it continues to shine brightly in your home or business environment.

Where to Buy 3M Perspex Sheet

Authorized Distributors and Retailers – Trusted suppliers for authentic products

When seeking authentic 3M Perspex sheet, choosing trusted suppliers is paramount to ensure quality and durability. In South Africa, authorized distributors and retailers serve as the gateways to genuine 3M Perspex sheet products, providing peace of mind for both commercial and DIY projects. These suppliers are carefully vetted to offer a wide range of options tailored to various applications—from intricate signage to industrial safety barriers.

To guarantee you receive the best product, it’s advisable to purchase from reputable sources that specialize in plastic sheets and have a proven track record. Some of the top authorized distributors include regional suppliers with extensive inventories of 3M Perspex sheet in different sizes, colors, and grades. These trusted partners often provide expert advice, helping customers select the ideal type of 3M Perspex sheet based on specific needs and environmental conditions.

- Visit official 3M distributor websites for a list of authorized retailers.

- Contact local plastic suppliers known for high-quality acrylic and polycarbonate sheets.

- Explore dedicated industrial supply companies with dedicated sections for 3M Perspex sheet products.

Whether you are outfitting a retail space or embarking on a home renovation, sourcing from authorized distributors guarantees you access to authentic 3M Perspex sheet—an investment in clarity, resilience, and aesthetic appeal that stands the test of time.

Online Shopping Options – Convenience and delivery considerations

Shopping for a 3M Perspex sheet online offers a level of convenience that would make even the most seasoned shopper do a double-take. No more wandering through endless aisles or battling traffic; your ideal acrylic or polycarbonate sheet is just a few clicks away. South Africa’s e-commerce platforms and industrial supply websites have stepped up to the plate, providing a seamless buying experience for those seeking authentic 3M Perspex sheet products.

However, before you hit the “buy now” button, consider delivery logistics. Opt for suppliers that offer reliable courier services, ensuring your 3M Perspex sheet arrives in pristine condition—no cracks, scratches, or warping allowed! Many online vendors also provide detailed product descriptions, size options, and even customer reviews, making it easier to match the right grade of 3M Perspex sheet to your specific project needs.

For a streamlined shopping experience, some platforms even feature:

- An extensive inventory of different sizes and colors

- Clear information on UV resistance and impact durability

- Expert support chat for instant guidance

Choosing a trusted online retailer ensures you’re getting genuine 3M Perspex sheet, avoiding the pitfalls of counterfeit products. Whether upgrading your retail signage or crafting a stunning DIY light fixture, online shopping for 3M Perspex sheet can be both efficient and satisfying—if you pick the right supplier, of course. Happy shopping!

Pricing and Bulk Purchase Benefits – Cost savings and volume discounts

Finding the right 3M Perspex sheet at the right price can make all the difference in your project’s success. Many suppliers in South Africa offer competitive pricing on 3M Perspex sheet, especially when purchasing in bulk. Volume discounts are a common incentive, allowing businesses and DIY enthusiasts alike to save significantly while acquiring larger quantities for demanding applications.

For those seeking cost-effective solutions, it’s worth exploring trusted online retailers or industrial supply platforms. These vendors often feature tiered pricing structures that cater to different purchase volumes, making it easier to maximize your budget. Some suppliers even provide transparent quotes for bulk orders, ensuring no surprises when it comes to costs.

- Compare prices across multiple vendors to identify the best deals on 3M Perspex sheet.

- Leverage volume discounts by purchasing larger sizes or multiple sheets to benefit from reduced unit costs.

- Look for suppliers offering free or discounted delivery on sizeable orders to further enhance savings.

Ultimately, choosing a supplier that offers both competitive pricing and reliable delivery ensures you get authentic 3M Perspex sheet at a price that aligns with your project’s scope. Whether it’s a small renovation or a large commercial build, the financial advantages of bulk purchasing are hard to ignore—especially when it guarantees high-quality, genuine 3M Perspex sheet for your application.

FAQs About 3M Perspex Sheet

Is 3M Perspex Sheet Safe for Outdoor Use? – Weather and UV resistance details

When it comes to outdoor installations, the question often arises: is the 3M Perspex sheet really up to the challenge? The answer is a resounding yes—if you choose the right grade, that is. 3M Perspex sheet offers impressive weather and UV resistance, making it suitable for a plethora of outdoor applications in South Africa. Whether you’re designing eye-catching signage or protective barriers, this acrylic marvel can withstand the harsh African sun without turning yellow or becoming brittle.

UV resistance is a standout feature, protecting your investment from the relentless rays that threaten to fade or degrade lesser materials. Weather resistance complements this, ensuring the 3M Perspex sheet remains clear, sturdy, and visually appealing over time. But beware—opt for a grade explicitly designed for outdoor use to ensure longevity. For added peace of mind, consider factors like thickness and color, which can influence weather resilience. With proper installation and maintenance, your 3M Perspex sheet will stay resilient, vibrant, and functional—no matter what the South African climate throws at it!

Can I Cut and Drill 3M Perspex Sheet Myself? – Tools and safety precautions

In the shadowed corridors of innovation, few materials evoke the same mystique and resilience as the 3M Perspex sheet. For those daring enough to shape light and form, the question often lingers: can I cut and drill this enigmatic acrylic without summoning disaster? The answer, cloaked in practicality and a touch of the arcane, is yes—if the right tools and precautions are employed. With the 3M perspex sheet, mastery begins with understanding its delicate strength. Proper cutting and drilling demand precision, patience, and respect for the material’s nature.

Before wielding your tools, ensure safety measures are in place—wear protective eyewear, gloves, and a dust mask. Use a fine-tooth blade or a specialized acrylic cutter for clean cuts, and drill at low speeds with a sharp, carbide-tipped drill bit. For a seamless finish, consider scoring and snapping or polishing edges afterward. Remember, a well-prepared workspace transforms the potentially hazardous into a craft of artistry. The 3M perspex sheet responds beautifully to careful handling, revealing its true potential when cut and drilled with finesse—an act akin to summoning light from darkness itself.

What Is the Difference Between Perspex and Acrylic? – Material properties and uses

In the realm where light dances upon surfaces and transparency whispers tales of innovation, the 3M perspex sheet stands as a testament to human ingenuity. Its crystalline clarity, combined with resilience that defies everyday wear, makes it a coveted material in both industrial and artistic pursuits. Yet, beneath its shimmering veneer lies a question that often ignites curiosity: what truly distinguishes perspex from acrylic? And how does the 3M perspex sheet elevate these differences into a craft, a science, a symphony of possibilities?

Perspex, in essence, is a brand name—an iconic term that has become synonymous with acrylic sheets. When we speak of 3M perspex sheet, we refer to a premium-grade acrylic material, renowned for its optical clarity, weather resistance, and ease of fabrication. The difference? Perspex often implies a specific quality standard, whereas acrylic encompasses a broader spectrum of plastics. The 3M perspex sheet shines brightest in applications demanding precision, durability, and aesthetic finesse—be it dazzling signage or delicate light diffusers.

Choosing the perfect 3M perspex sheet involves considerations both practical and poetic. Thickness, size, and color must harmonize with your vision, while the grade dictates its resilience against impact and weathering. Whether you seek a lightweight yet robust acrylic for a retail display or a weather-resistant sheet for outdoor signage, the 3M perspex sheet offers a palette of options that cater to diverse needs. Its impact resistance and optical clarity are unmatched, transforming mere sheets into portals of possibility.

How Long Does 3M Perspex Sheet Last? – Lifespan and care tips

When it comes to the longevity of a 3M perspex sheet, think of it as the superhero of acrylics—resilient, charming, and ready to withstand the test of time. Typically, with proper care, a high-quality 3M perspex sheet can last anywhere from 10 to 20 years. Yes, you read that right—two whole decades of clear, impact-resistant brilliance! But, like any hero, it needs a little TLC now and then.

To ensure your 3M perspex sheet maintains its pristine appearance and durability, regular cleaning and gentle handling are essential. Avoid harsh chemicals that can dull its optical clarity and scratch-resistant surface. Instead, opt for a soft cloth and a mild soap solution—your sheet will thank you with years of unwavering transparency.

Some users find that they need to replace their 3M perspex sheet sooner if exposed to extreme elements or rough handling. Here’s a quick rundown of care tips:

- Keep it clean and dry—dirt and moisture are the sneaky culprits behind cloudiness and degradation.

- Avoid sharp objects—scratches not only mar the aesthetic but can compromise impact resistance.

- Protect it from prolonged direct sunlight—although UV resistant, excessive exposure can accelerate discoloration.

In the grand scheme of things, the longevity of a 3M perspex sheet is a testament to its quality, with many users enjoying its crystal-clear charm for well over a decade—proof that investing in premium acrylic like a 3M perspex sheet truly pays off in durability and aesthetic appeal.

0 Comments