Understanding Acrylic Sheets

What Are Acrylic Sheets? – Definition and general characteristics of acrylic sheets

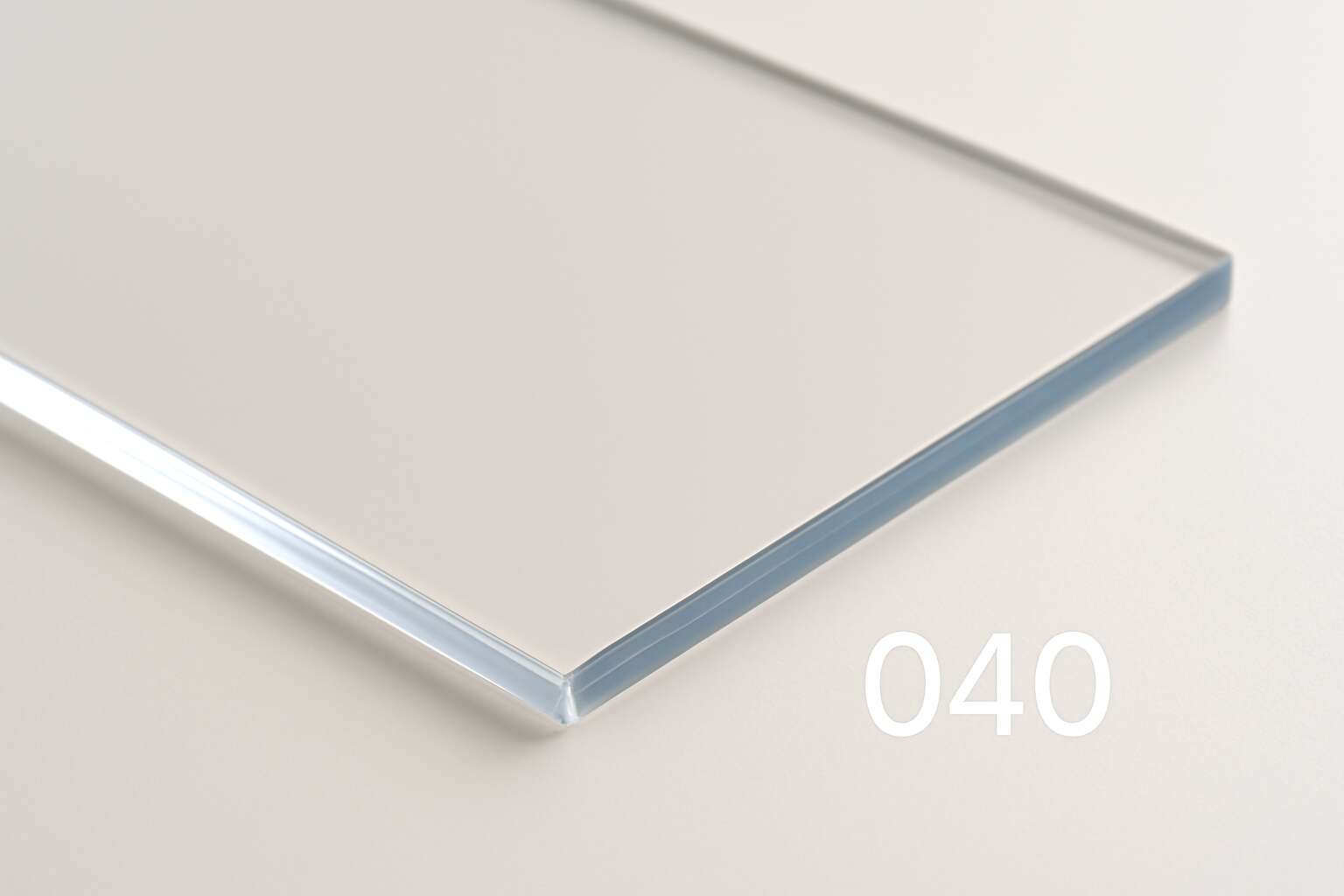

In the vast landscape of modern materials, acrylic sheet 040 stands out as a testament to versatility and resilience. Its crystalline clarity and lightweight nature make it an exceptional choice for applications demanding transparency and durability. When we speak of acrylic sheets, we refer to a synthetic polymer known as polymethyl methacrylate (PMMA), celebrated for its high optical clarity and ease of fabrication.

Unlike traditional glass, acrylic sheet 040 offers an impressive combination of strength and flexibility. Its resistance to impact surpasses that of glass, making it an ideal option for both decorative and structural purposes. This specific grade, acrylic sheet 040, is characterized by its thickness, typically around 4mm, striking a perfect balance between robustness and workability. Whether used in signage, display units, or architectural features, the unique properties of acrylic sheet 040 make it an invaluable resource for innovative design in South Africa’s diverse environment.

Understanding the defining traits of acrylic sheet 040 opens the door to endless creative possibilities. Its optical clarity, combined with excellent weather resistance, ensures that projects not only look stunning but also stand the test of time. This material’s adaptability is further enhanced by its compatibility with various finishing techniques, from polishing to engraving, enabling customization that meets the most exacting specifications.

Types of Acrylic Sheets – Different variants available in the market

Within the kaleidoscope of acrylic possibilities, acrylic sheet 040 emerges as a distinguished variant, tailored for those seeking a harmonious blend of strength and finesse. Its unique composition lends itself to a spectrum of applications, from intricate signage to architectural accents, capturing light with a crystalline brilliance. But did you know that acrylic sheets are not a monolith? Far from it, they come in a variety of forms, each whispering a different promise of performance and aesthetic allure.

Among these, the most prevalent types include cast acrylic, extruded acrylic, and specialty variants such as UV-resistant or flame-retardant acrylic sheets. For instance, cast acrylic, celebrated for its superior optical clarity and polished finish, often finds favor in high-end displays. Meanwhile, extruded acrylic, with its enhanced flexibility and cost-efficiency, is ideal for large-scale projects that demand uniform thickness and ease of fabrication.

When considering acrylic sheet 040, it’s essential to understand its place within this diverse family. Its 4mm thickness strikes a delicate balance, making it versatile enough for a multitude of tasks—whether it’s a sleek display case or a resilient architectural panel. Each type of acrylic sheet caters to specific needs, allowing designers and engineers in South Africa to craft with confidence and precision, knowing the material’s inherent qualities align seamlessly with their vision!

Common Uses and Applications – Industries and projects utilizing acrylic sheets

Acrylic sheet 040 captures the imagination with its perfect balance of clarity and durability, making it a staple across a spectrum of industries in South Africa. Its versatility lends itself beautifully to projects that demand both aesthetic finesse and resilience. From sleek retail displays to sophisticated architectural features, this 4mm thick sheet transforms visions into tangible realities with crystalline brilliance.

Within the realm of common uses, acrylic sheet 040 is often chosen for signage, where its optical clarity ensures that branding messages shine brightly. It is also a favored material for creating protective covers, light diffusers, and decorative panels. In the realm of architecture, this sheet lends a polished, modern touch to interior accents and façade elements, blending form with function seamlessly.

Its adaptability extends further to projects such as:

- Display cases in retail environments

- Lighting fixtures that require diffused illumination

- Custom furniture pieces with a contemporary edge

In South Africa, where innovation meets practicality, acrylic sheet 040 continues to be a material of choice for architects and designers alike, embodying the promise of beauty and strength in every application.

Introduction to Acrylic Sheet 040

What Is Acrylic Sheet 040? – Specific features and specifications

When it comes to transparent versatility, acrylic sheet 040 stands out like a superstar in the world of plastics. Known for its crystal-clear appearance and lightweight resilience, acrylic sheet 040 offers a perfect blend of durability and aesthetic appeal. Unlike traditional glass, it’s less prone to shattering—making it the go-to choice for displays, signage, and protective barriers in South Africa’s bustling commercial spaces. What truly sets acrylic sheet 040 apart are its specific features: excellent optical clarity, high impact resistance, and ease of fabrication. Whether you’re creating a statement piece or a functional partition, this variant ensures your project remains both stylish and practical.

In terms of specifications, acrylic sheet 040 typically boasts a thickness of 4mm, striking an ideal balance between sturdiness and flexibility. Its chemical composition lends it remarkable weather resistance, making it suitable for outdoor installations where South Africa’s sun can be unforgiving. As a bonus, acrylic sheet 040 is easy to cut, drill, and bend—saving time and labor costs. For those seeking a product that combines high performance with cost-effectiveness, acrylic sheet 040 is undeniably a material worth considering. From retail displays to DIY projects, its specific features make it the unsung hero of many creative endeavors.

Material Composition and Thickness – Details about its thickness and material properties

Acrylic sheet 040 is renowned for its precise thickness and remarkable material properties, making it an essential choice for diverse applications across South Africa. Its standard thickness of 4mm strikes a perfect balance—robust enough to provide durability yet flexible enough for intricate fabrication. This thickness lends itself well to both structural and aesthetic projects, from display cases to decorative partitions.

At the core of acrylic sheet 040’s excellence is its unique chemical composition. Crafted from polymethyl methacrylate (PMMA), it boasts clarity and weather resistance that surpass many other plastics. Its high optical transparency ensures that light passes through with minimal distortion, enhancing visual appeal in retail displays and signage. Additionally, the material’s inherent resilience against UV exposure and harsh outdoor conditions makes it ideal for South Africa’s often unforgiving sunlight.

Furthermore, acrylic sheet 040’s ease of fabrication is a standout feature. Its versatility allows for simple cutting, drilling, and bending, streamlining manufacturing processes and reducing labor costs. This combination of reliable thickness and superior material qualities positions acrylic sheet 040 as a preferred material for both functional and decorative projects, fulfilling the needs of professionals seeking high performance and aesthetic excellence.

Advantages of Using Acrylic Sheet 040 – Benefits over other types or materials

In the realm of versatile building materials, acrylic sheet 040 stands out as a shining example of innovation and resilience. Its remarkable clarity and durability make it a favorite among architects, designers, and craftsmen across South Africa. The beauty of acrylic sheet 040 lies not only in its aesthetic appeal but also in its ability to withstand the country’s often harsh outdoor conditions. This makes it an invaluable asset for projects demanding both form and function.

Choosing acrylic sheet 040 offers numerous benefits over traditional materials like glass or polycarbonate. Its lightweight nature simplifies handling and installation, reducing labour costs and time. Moreover, its exceptional optical transparency ensures that light passes through with minimal distortion, elevating visual displays and signage. For professionals seeking a blend of strength and style, acrylic sheet 040 provides an unmatched balance—delivering durability without sacrificing design flexibility.

Technical Specifications of Acrylic Sheet 040

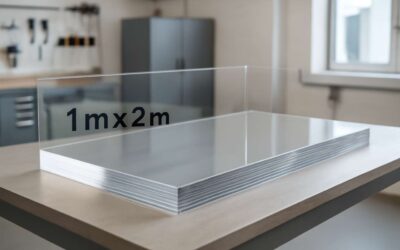

Dimensions and Sizes – Standard and custom sizes available

When it comes to the technical specifications of acrylic sheet 040, precision is paramount. This variant boasts a standard thickness of 3mm, but custom sizes are readily available to meet unique project demands. Manufacturers often produce acrylic sheet 040 in sheets measuring up to 2440mm by 1220mm, ensuring versatility for both small-scale and large-scale applications. The dimensions are carefully engineered to provide optimal clarity and strength, making it a favorite in architectural and signage projects across South Africa.

For those seeking tailored solutions, custom sizes can be fabricated seamlessly—whether it’s a bespoke panel for a bold installation or specific cutouts for intricate designs. The material’s durability is matched by its flexibility, allowing for complex shaping without compromising integrity. This adaptability makes acrylic sheet 040 an essential choice for professionals aiming to combine aesthetic appeal with functional reliability. Its precise dimensions and customizable options unlock countless possibilities, elevating projects to a new level of excellence.

Color and Transparency – Color options and clarity levels

When it comes to acrylic sheet 040, color and transparency are where this versatile material truly shines. Its crystal-clear clarity transforms any project into a luminous masterpiece, allowing light to pass through with minimal distortion. Whether for intricate signage or delicate displays, the transparency level of acrylic sheet 040 ensures that your design remains vibrant and eye-catching.

In addition to its transparency, the color options for acrylic sheet 040 are surprisingly broad, offering everything from pristine clear to subtle tints that enhance aesthetic appeal. Some manufacturers even produce tinted variants in shades like smoky gray, vibrant blue, or warm amber, giving designers the flexibility to craft unique visual effects. This color versatility makes acrylic sheet 040 a favorite in architectural accents and decorative installations across South Africa.

For projects demanding specific hues or visual effects, custom color formulations are readily available. This adaptability means you can achieve the perfect ambiance, whether aiming for understated elegance or bold statement pieces. With its superb clarity and a rainbow of color options, acrylic sheet 040 unlocks endless creative possibilities, elevating your projects to extraordinary heights!

Mechanical Properties – Strength, impact resistance, flexibility

When considering acrylic sheet 040, understanding its mechanical properties is crucial for any project demanding durability and resilience. This specific variant exhibits impressive strength, capable of withstanding substantial loads without cracking or deforming. Its impact resistance is equally remarkable, enabling it to absorb shocks that would shatter lesser materials, making it ideal for high-traffic areas or environments prone to accidental impacts.

Flexibility is another standout feature of acrylic sheet 040. Despite its robust nature, it can be bent or shaped with relative ease, provided the right techniques are applied. This combination of strength and flexibility opens a world of creative possibilities, especially in architectural and decorative applications across South Africa. For example, it can be curved into complex forms or cut precisely for intricate designs, all while maintaining structural integrity.

In terms of specific properties, acrylic sheet 040 typically boasts a tensile strength of around 70 MPa and an impact strength of approximately 20-30 times higher than glass. These attributes ensure that the material not only performs under demanding conditions but also contributes to safety and longevity in your projects. Its resilience makes it a preferred choice among professionals seeking a durable, high-performance acrylic sheet 040 that balances strength with versatility.

Thermal & UV Resistance – Performance in varying environmental conditions

In the ever-changing South African climate, where temperatures can swing from scorching heat to icy chills within a matter of hours, understanding the thermal and UV resistance of acrylic sheet 040 becomes paramount. This variant is designed to perform reliably in a variety of environmental conditions, ensuring your installations withstand the rigours of nature without succumbing to warping or discoloration. Its robust UV resistance safeguards it from the sun’s relentless rays, preventing degradation and maintaining clarity over time.

For projects exposed to sunlight or fluctuating temperatures, acrylic sheet 040 offers exceptional durability. Its performance is further enhanced by the ability to endure high temperatures without losing shape or integrity. In environments where exposure to weather elements is inevitable, this material remains resilient, maintaining aesthetic appeal and structural stability.

Moreover, the thermal stability of acrylic sheet 040 makes it suitable for applications where temperature fluctuations are common. Whether used in outdoor signage, protective glazing, or architectural features, this acrylic variant consistently proves its mettle. Its capacity to withstand varying environmental conditions without cracking or yellowing is why it continues to be a preferred choice among South African architects and builders alike.

Laser and CNC Compatibility – Ease of fabrication

In the realm of precision fabrication, the technical specifications of acrylic sheet 040 stand as a testament to its versatility and adaptability. Crafted with meticulous attention to detail, this acrylic variant boasts a smooth surface finish that lends itself beautifully to laser and CNC cutting processes. Its uniform thickness ensures consistent results, making it an ideal choice for intricate designs and detailed craftsmanship.

Compatibility with laser and CNC machinery is a standout feature of acrylic sheet 040. Thanks to its high optical clarity and stable composition, it responds predictably to laser engraving and cutting, resulting in crisp, clean edges. For those in South Africa seeking ease of fabrication, this acrylic sheet simplifies the production process, reducing wastage and enhancing precision.

- Exceptional machinability that allows for complex shapes and detailed patterns.

- High tolerance levels, ensuring uniformity across varied projects.

- Compatibility with a wide range of fabrication tools, from laser engravers to CNC routers.

Whether you are creating custom signage, architectural features, or protective glazing, acrylic sheet 040’s technical prowess ensures your project’s success. Its ease of fabrication not only accelerates production timelines but also elevates the quality of finished work, making it a preferred material among South African architects, designers, and manufacturers. The seamless integration with laser and CNC technologies unlocks a world of creative potential, transforming ideas into tangible masterpieces with effortless precision.

Applications of Acrylic Sheet 040

Design and Architectural Uses – Signage, interiors, partitions

In the world of design and architecture, acrylic sheet 040 stands out as a versatile material capable of transforming spaces with ease. Its clarity and durability make it an ideal choice for applications that demand both aesthetic appeal and resilience. From eye-catching signage to sleek interior accents, acrylic sheet 040 offers a seamless blend of form and function that captivates the eye and withstands the test of time.

Architects and interior designers are increasingly turning to acrylic sheet 040 for partitions that create open, airy environments while maintaining privacy. Its lightweight nature simplifies installation, reducing project timelines and costs. For signage, the smooth surface of acrylic sheet 040 lends itself perfectly to vibrant graphics and illuminated displays, making brands pop with a supernatural glow that draws attention effortlessly.

- Customizable in various sizes and thicknesses

- Excellent optical clarity maximizes visual impact

- Resistant to UV and weather conditions, suitable for outdoor signage

In the realm of architectural design, acrylic sheet 040’s adaptability allows it to become anything from a modern skylight to decorative wall panels. Its ability to be fabricated using laser and CNC technology ensures precision, enabling architects to push creative boundaries while maintaining structural integrity. This material’s multifaceted nature makes it an essential element in South African projects aiming for innovation and durability.

Industrial and Commercial Applications – Displays, protective barriers

In the shadowy corridors of industry and commerce, acrylic sheet 040 casts a luminous glow of innovation. Its robust yet pliable nature makes it an ideal choice for displays that demand both clarity and impact. From retail showcases to exhibition booths, this material transforms ordinary spaces into captivating realms of visual storytelling. Its excellent optical properties ensure every detail is crisp, while its resistance to UV and weathering guarantees longevity in outdoor environments.

For protective barriers—an essential fixture in today’s world—acrylic sheet 040 provides a formidable shield without sacrificing transparency. Whether shielding staff in bustling retail outlets or creating safety partitions in industrial settings, it combines strength with aesthetic grace. Its ease of fabrication through laser and CNC technology allows for precise shaping, fitting seamlessly into complex architectural schemes. The dark elegance of acrylic sheet 040 elevates functional design into an art form, making it a preferred material for those who seek both resilience and refinement.

Home and DIY Projects – Innovative uses for homeowners and hobbyists

Transform your home and DIY projects into enchanting realms with the versatile potential of acrylic sheet 040. Its crystalline clarity and resilient nature make it a favorite among homeowners and hobbyists eager to infuse their creations with both beauty and durability. Whether crafting custom picture frames, elegant display cases, or innovative lighting covers, acrylic sheet 040 lends a professional finish that elevates any project beyond the ordinary.

One of the most compelling aspects of acrylic sheet 040 is its ease of fabrication. Its compatibility with laser and CNC cutting techniques opens a world of possibilities for intricate designs and precise shaping. Imagine creating personalized shelving units or decorative panels that seamlessly blend form and function. For those seeking to add a touch of sophistication, acrylic sheet 040’s transparent elegance can be tinted or colored, offering a palette of customization options.

Here are some inspiring ways to incorporate acrylic sheet 040 into your home or hobby endeavors:

- Constructing bespoke display cabinets to showcase cherished collectibles

- Designing modern, lightweight partitions for open-plan living spaces

- Creating protective covers for delicate artwork or electronic devices

From vivid craft projects to practical home improvements, acrylic sheet 040’s unique properties make it an indispensable material for the creative enthusiast. Its resilience against impact and weathering ensures that your handmade creations will stand the test of time, turning everyday spaces into personal works of art. In the realm of DIY, few materials rival the adaptability and allure of acrylic sheet 040—an enchanted resource waiting to be unleashed in every home.

Comparing Acrylic Sheet 040 with Other Options

Acrylic vs Polycarbonate – Key differences and use cases

In the realm of transparent and durable materials, acrylic sheet 040 emerges as a true marvel—combining clarity with strength, tailored perfectly for diverse applications. Yet, when comparing acrylic sheet 040 with other options like polycarbonate, the distinctions become vital for selecting the optimal material for your project. Polycarbonate, often celebrated for its impact resistance, surpasses acrylic sheet 040 in toughness but falls short in UV stability and optical clarity. For projects demanding superior visual transparency and ease of fabrication, acrylic sheet 040 offers an unrivaled balance.

While acrylic sheet 040 is ideal for signage, architectural features, and retail displays, polycarbonate’s resilience makes it suitable for protective barriers and safety glazing. The key differences can be summarized as:

- Impact resistance: Polycarbonate outperforms acrylic sheet 040.

- Optical clarity: Acrylic excels with higher transparency.

- UV stability: Acrylic sheet 040 resists yellowing over time better than polycarbonate.

Understanding these nuances ensures your choice aligns with your specific use case, whether aiming for crystal-clear displays or rugged, impactproof barriers. Acrylic sheet 040 stands as a sophisticated option that fuses aesthetic elegance with practical longevity, distinguishing itself in the competitive landscape of plastic materials.

Acrylic vs Glass – Advantages in transparency, weight, and durability

When comparing acrylic sheet 040 with traditional glass, the differences are striking—yet often underestimated. Acrylic sheet 040 boasts superior impact resistance, making it a safer choice in environments prone to accidental bumps or falls. Unlike glass, which can shatter into dangerous shards, acrylic retains its integrity, providing peace of mind and enhanced durability.

Furthermore, acrylic sheet 040 is remarkably lighter than glass, easing handling and installation. Its optical clarity rivals that of glass, ensuring pristine transparency that highlights vibrant visuals without distortion. Thanks to its advanced manufacturing, acrylic sheet 040 also offers better resistance to scratches and UV degradation, maintaining its brilliance over time.

- Impact resistance surpasses that of glass, reducing breakage risk.

- Weight advantages simplify transportation and installation.

- Superior optical clarity preserves visual integrity for displays and glazing.

In environments where safety, clarity, and ease of fabrication are paramount, acrylic sheet 040 emerges as an unbeatable alternative to glass. Its unique blend of resilience and transparency secures its position as a premium choice for both commercial and residential applications across South Africa.

Acrylic Sheet 040 vs Other Thicknesses – Specific benefits of the 040 variant

When selecting the ideal acrylic sheet for your project, understanding the nuances of thickness options can make all the difference. The acrylic sheet 040 stands out as a versatile choice, perfectly balancing strength and manageability. Compared to thicker variants, such as 060 or 080, the acrylic sheet 040 offers a refined blend of impact resistance and lightweight handling, making it especially suitable for intricate installations and delicate designs.

This specific thickness provides remarkable clarity and ease of fabrication, allowing for sharper cuts and cleaner finishes. For applications demanding a sleek, modern aesthetic—think signage or display cases—the acrylic sheet 040’s transparency and finesse are unmatched. Its moderate thickness ensures durability without sacrificing visual purity, making it the preferred option in both commercial and residential environments across South Africa.

- Impact resistance remains high, reducing the risk of breakage during handling.

- Lightweight nature simplifies transportation and installation processes.

- Its balance of thickness and flexibility lends itself well to custom cuts and detailed designs.

In essence, the acrylic sheet 040 exemplifies the perfect middle ground—offering a sturdy yet elegant solution that elevates any project with its clarity, resilience, and ease of use. This makes it an indispensable choice when precision and safety are paramount in your architectural or creative endeavors.

Buying Guide for Acrylic Sheet 040

Where to Purchase – Online vs local distributors

Choosing the right source for acrylic sheet 040 can feel like navigating a labyrinth—do you opt for the convenience of online shopping or the assurance of local distributors? Interestingly, over 70% of buyers prefer online platforms for their vast selection and competitive prices, yet many still trust regional suppliers for personalized service and immediate availability.

When purchasing acrylic sheet 040, it’s essential to consider quality, authenticity, and after-sales support. Online marketplaces often offer detailed specifications, customer reviews, and easier price comparisons. Conversely, local distributors provide tactile inspection and instant pickup, which can be crucial for urgent projects.

For a seamless experience, some buyers opt for a hybrid approach—ordering online for bulk or specialty sheets while sourcing smaller quantities locally. This approach ensures they get the best of both worlds: convenience and confidence in the product’s authenticity.

Factors to Consider – Quality, thickness, supplier reputation

Choosing the perfect acrylic sheet 040 is akin to selecting a canvas where your vision takes shape—each detail matters. When evaluating quality, inspect the clarity and uniformity of the acrylic sheet 040; a pristine surface free from bubbles, scratches, or discoloration signals superior craftsmanship. Thickness plays a pivotal role too—ensuring the sheet’s robustness and suitability for your project’s demands. A thicker acrylic sheet 040 offers enhanced durability, impact resistance, and structural integrity, making it ideal for both aesthetic and functional applications.

Reputation of the supplier must not be overlooked. A trusted distributor guarantees authentic acrylic sheet 040, backed by reliable after-sales support. To navigate this landscape with confidence, consider a supplier’s track record, customer reviews, and certifications. For added assurance, some buyers prefer to request samples or detailed specifications before committing to a purchase—ensuring their chosen acrylic sheet 040 aligns perfectly with their project needs.

In the realm of acrylic sheet 040, a discerning eye for quality and reputation transforms a simple purchase into a foundation for excellence. Whether sourcing from local distributors or online platforms, these considerations serve as guiding stars in your pursuit of the ideal acrylic sheet 040 for your endeavor.

Pricing and Budgeting – Cost factors and value for money

Pricing for acrylic sheet 040 varies widely, and understanding the cost factors is essential to maximize value for money. While some suppliers offer affordable options, it’s vital to recognize that lower prices can sometimes reflect compromised quality or durability. The true challenge lies in balancing cost with the long-term benefits that acrylic sheet 040 provides—impact resistance, clarity, and versatility. In South Africa, market fluctuations and import tariffs influence pricing, making it crucial to evaluate not just the sticker price but the overall value.

When budgeting for your project, consider the following factors that influence the cost of acrylic sheet 040:

- Material quality and clarity

- Thickness and dimensions

- Supplier reputation and certification

- Additional treatments or customizations

Some suppliers may offer volume discounts or promotional deals, but always scrutinize these offers for authenticity. Remember, investing in a high-quality acrylic sheet 040 from a reputable distributor ensures a product that performs reliably and lasts longer, ultimately delivering better value in the end. As the adage suggests, you often get what you pay for—so weigh the price against the potential longevity and performance of your acrylic sheet 040 to make an informed decision that aligns with your project’s ambitions.

Maintenance and Care – Cleaning tips and longevity

Maintaining the pristine clarity and impact resistance of acrylic sheet 040 requires thoughtful care. Unlike traditional glass, acrylic sheets demand gentle cleaning to preserve their optical brilliance and structural integrity. Regularly wiping the surface with a soft, damp cloth prevents dust and grime from settling, which can cause micro-scratches or dullness over time.

For more stubborn marks, a mild soap solution or a specialized acrylic cleaner is ideal. Avoid abrasive cleaners or rough scrubbing pads—they can damage the surface and compromise the impact resistance of acrylic sheet 040. When cleaning, always use a circular motion to minimize surface scratches and maintain the sheet’s transparency.

Longevity hinges on proper maintenance, especially in South Africa’s diverse climate. UV exposure and temperature fluctuations can affect the material’s performance; hence, periodic inspections are recommended. If you notice any clouding or surface damage, consulting a professional for appropriate treatments can extend the lifespan of your acrylic sheet 040 significantly.

To further ensure durability, consider applying a protective film during installation or transport. This layer acts as a shield against scratches and environmental contaminants, helping you enjoy the full benefits of acrylic sheet 040 for years to come. Remember, the key to maximizing your investment lies in gentle handling and routine care—your acrylic sheet 040 will thank you with enduring clarity and resilience!

Installation and Fabrication Tips

Tools Needed – Recommended equipment

When embarking on a project using acrylic sheet 040, precision and the right tools are paramount. Proper installation and fabrication not only ensure a polished finish but also extend the lifespan of your acrylic components. To achieve this, having the correct equipment on hand can make all the difference.

Begin with a sharp, fine-toothed saw specifically designed for acrylic, such as a plastic-cutting blade, to make clean, accurate cuts without cracking or melting the material. A variable-speed jigsaw can also be helpful for intricate shapes, but always ensure it’s fitted with a suitable blade. For smooth edges and polished surfaces, a sanding block or fine-grit abrasive pads are essential. Safety gear like gloves and goggles should never be overlooked, as acrylic dust and shards can pose hazards.

To streamline your fabrication process, consider using a clamps or vacuum suction cups to hold the acrylic securely during cutting or drilling. When drilling, a drill bit designed for plastics, along with a slow, steady hand, prevents cracking and produces neat holes. For edge finishing, a deburring tool can help achieve a flawless, professional look. Incorporating these recommended tools into your toolkit guarantees that your acrylic sheet 040 project proceeds seamlessly, resulting in a durable and aesthetically pleasing finish.

Cutting and Drilling – Best practices for shaping acrylic sheet 040

Shaping acrylic sheet 040 isn’t just about wielding a saw and hoping for the best; it’s an exercise in finesse and precision. When cutting acrylic sheet 040, the goal is to avoid the dreaded cracks or melting that can turn your project into a tragic comedy. Opt for a fine-toothed, plastic-specific blade—think of it as the scalpel of your toolkit. This ensures clean, sharp edges that won’t leave you lamenting over imperfections.

For drilling, patience is a virtue. Use a drill bit designed specifically for plastics, and take it slow—rushing can cause cracks or bubbles. To keep everything steady, clamps or vacuum suction cups are your best friends, holding the acrylic sheet 040 firmly in place. When it comes to shaping intricate designs, a variable-speed jigsaw fitted with a suitable blade can work wonders. Remember, gentle, steady pressure is key to avoiding stress fractures in the material.

Once the cutting and drilling are done, smoothing out rough edges with a sanding block or fine-grit abrasive pads makes all the difference—giving your acrylic sheet 040 a professional finish that looks as good as it performs. For edge finishing, a deburring tool can help achieve that sleek, polished look.

- Always wear safety goggles and gloves—acrylic dust and shards are no joke.

By following these best practices, your acrylic sheet 040 project will not only turn out stunning but will also stand the test of time, proving that good craftsmanship is all about precision and patience.

Joining Techniques – Bonding, gluing, and fastening methods

In the shadowed corridors of craftsmanship, the true mastery of acrylic sheet 040 reveals itself not merely through creation but through the silent dance of precision and patience. When it comes to installation and fabrication, the devil is in the details—each joining method a delicate spell cast to unite strength and beauty. Bonding techniques such as solvent cement glues forge transparent, almost mystical connections, transforming fractured fragments into seamless illusions of unity. Meanwhile, mechanical fastening with screws or rivets offers a rugged resilience, perfect for projects demanding a fortress of durability.

For those seeking ultimate finesse, the artistry of joining acrylic sheet 040 lies in selecting the right method. An ordered approach—like threading the strands of a dark tapestry—ensures each piece aligns with the other, avoiding stress fractures and unsightly blemishes. A simple list of techniques can serve as your guide:

- Use acrylic-specific adhesives for invisible bonds that mimic the sheet’s natural clarity.

- Employ clamps or specialized jigs to hold pieces securely during the bonding process, preventing shifts that could mar the surface.

- Consider thermal welding for larger, more intricate assemblies—merging the material at a molecular level for enduring strength.

When it comes to fastening, never underestimate the power of subtlety. Hidden fasteners or countersunk screws can maintain the sleek aesthetic of your acrylic sheet 040 while providing substantial support. For decorative or structural joints, specialized glazing tapes or brackets can add an element of sophistication, whispering promises of longevity. As you weave together these elements, remember: the true magic lies in the harmony of method and material, where each connection echoes the dark elegance of a well-crafted piece.

Safety Precautions – Handling and installation safety

Handling acrylic sheet 040 requires a delicate touch and a respect for its fragile elegance. Despite its impressive resilience, mishandling can lead to surface scratches or stress fractures that mar its pristine clarity. Safety precautions are essential to ensure that your project remains flawless and safe for everyone involved. Always wear protective gloves and goggles—acrylic dust and shards can be unexpectedly sharp, especially during cutting or drilling.

When installing or fabricating acrylic sheet 040, work in a well-ventilated area to avoid inhaling fumes from solvents or adhesives. Secure the sheet firmly using clamps or specialized jigs to prevent slips that could cause damage or injury. Remember, patience is your ally—rushing can result in uneven cuts or unintended stress points. For intricate tasks, consider using a protective backing or masking tape to shield the surface from scratches during handling.

- Use the correct tools designed for acrylic, such as fine-tooth saw blades and sharp drills, to maintain clean edges and prevent cracks.

- Always test your bonding or fastening method on a scrap piece to ensure compatibility and achieve optimal results.

Above all, prioritize safety—your craftsmanship depends on it. Proper handling not only preserves the integrity of the acrylic sheet 040 but also ensures a smooth, professional finish that celebrates the material’s transparency and strength. Remember, the magic of acrylic lies in its pristine clarity, so treat it with care and respect at every turn!

Environmental Impact and Sustainability

Recycling and Disposal – Proper methods for environmental safety

In a world increasingly conscious of environmental footprints, understanding the sustainability of materials like acrylic sheet 040 is more crucial than ever. While acrylic sheet 040 offers remarkable clarity and durability, its environmental impact is a topic gaining attention among eco-aware professionals in South Africa. Proper recycling and disposal methods are essential to ensure that the benefits of acrylic do not come at the planet’s expense.

Recycling acrylic sheet 040 is straightforward but requires adherence to specific procedures to prevent environmental harm. When disposed of incorrectly, acrylic waste can linger in landfills for decades, slowly breaking down and releasing microplastics. To mitigate this, scrap acrylic sheets should be taken to certified recycling centers equipped to handle acrylic materials. These facilities process the acrylic into granules that can be reused in manufacturing new products, reducing the need for virgin plastic production.

For safe disposal, avoid burning acrylic, as it releases toxic fumes harmful to both humans and the environment. Instead, consider repurposing leftover acrylic sheet 040 for DIY projects or donating unused pieces to community workshops. Implementing these practices aligns with sustainable principles and helps South Africa meet its environmental commitments.

Eco-Friendly Alternatives – Sustainable options in acrylic manufacturing

Environmental impact is a growing concern when choosing materials like acrylic sheet 040. While this versatile plastic offers exceptional clarity and durability, its sustainability depends on responsible manufacturing and disposal. In South Africa, eco-conscious professionals are seeking eco-friendly alternatives that reduce landfill waste and microplastic pollution.

Fortunately, advancements in acrylic manufacturing have introduced sustainable options. Some producers now incorporate recycled acrylic or bio-based polymers, making acrylic sheet 040 a more environmentally responsible choice. These innovations help lower carbon footprints and conserve natural resources. Moreover, recycling acrylic sheet 040 isn’t just feasible — it’s essential. Certified recycling centers can process scrap acrylic into reusable granules, closing the loop in the material’s lifecycle.

For those committed to sustainability, consider using acrylic sheet 040 with eco-friendly certifications or opting for repurposed pieces. Implementing these options aligns with global efforts to promote green manufacturing and waste reduction. As awareness around environmental impact deepens, the industry continues to evolve, offering more sustainable solutions for acrylic applications in South Africa.

0 Comments