Understanding Acrylic Sheets and Their Applications

Types of Acrylic Sheets

In the realm of modern architecture and innovative design, acrylic sheets have transcended their traditional roles to become symbols of transparency and resilience. These sheets are not merely sheets; they are the canvas upon which creativity and engineering intersect. Understanding acrylic sheets involves appreciating their versatility—ranging from crystal-clear displays to structural components that challenge the very notions of strength and flexibility. When it comes to the acrylic sheet joint, precision becomes paramount, as these joints dictate the integrity and aesthetic harmony of the entire structure.

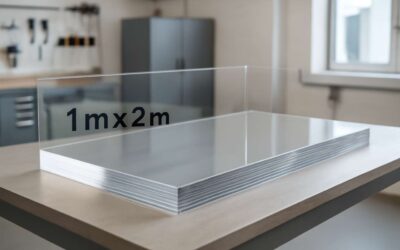

Different types of acrylic sheets cater to varied applications, each with unique characteristics that influence how they are joined. For instance, extruded acrylic sheets are popular for their affordability and ease of fabrication, while cast acrylic sheets boast superior optical clarity and durability. The choice of acrylic sheet for a project often hinges on the specific demands of the environment and the visual effect desired. Whether for decorative installations, protective barriers, or light fixtures, selecting the right acrylic sheet type is a decisive step that influences the longevity and visual appeal of the finished product.

Common Uses of Acrylic Sheets

Across the vast landscapes of South Africa, the allure of acrylic sheets has woven itself into the fabric of modern design and structural innovation. These sheets, shimmering like enchanted glass, serve as the backbone of many creative endeavors, from vibrant storefront displays to resilient protective barriers. Their versatility is unmatched—capable of transforming a simple space into a realm of luminous possibility. Yet, what truly holds these luminous visions together is the mastery of the acrylic sheet joint, a delicate yet powerful element that ensures both strength and seamless beauty.

In the realm of applications, acrylic sheets are often chosen for their clarity and durability, making them ideal for use in installations where visual impact is paramount. Common uses include light fixtures that cast a magical glow over interior spaces, decorative panels that add an ethereal touch, and even structural components in aquariums or display cases. When working with an acrylic sheet joint, precision is essential; it not only affects the structural integrity but also the enchanting visual harmony of the entire piece. Properly crafted joints elevate an ordinary installation into a masterpiece of engineering and artistry.

Benefits of Using Acrylic Sheets

Understanding acrylic sheets and their applications is like unlocking a secret superpower in the world of design and engineering. These sheets are not just shiny, transparent panels; they’re versatile marvels that bring both function and flair to countless projects. Their ability to mimic glass while offering superior durability makes them a favorite for everything from sleek retail displays to innovative architectural elements.

One of the key factors that elevate their potential is the acrylic sheet joint. When two sheets come together, a well-executed joint isn’t just about strength—it’s about creating a seamless visual flow that captivates without distraction. The benefits of using acrylic sheets extend beyond aesthetics. They’re lightweight, weather-resistant, and easy to manipulate, making them ideal for both indoor and outdoor applications.

In fact, the mastery of the acrylic sheet joint can turn an ordinary installation into a work of art. Properly bonded joints ensure safety, longevity, and a pristine appearance that withstands the test of time and environmental challenges. Whether you’re assembling a protective barrier or designing a luminous display, understanding the nuances of the acrylic sheet joint is crucial for achieving flawless results. After all, a stunning project is only as strong as its joints!

Importance of Proper Acrylic Sheet Joints

Structural Integrity

In the world of acrylic sheet applications, the importance of a properly executed acrylic sheet joint cannot be overstated. A seamless, durable joint is the backbone of structural integrity, ensuring that the entire assembly withstands environmental stresses and daily wear. When joints are weak or improperly aligned, the entire structure risks failure, leading to costly repairs and safety hazards that could have been prevented.

Understanding the nuances of an effective acrylic sheet joint goes beyond mere aesthetics; it’s about creating a resilient barrier that maintains clarity, strength, and longevity. The integrity of these joints directly impacts the performance of façades, display cases, or any project where transparency and strength are paramount. As such, meticulous attention to joint design and execution is essential to uphold both safety standards and the visual appeal that acrylic sheets offer.

In essence, a well-crafted acrylic sheet joint is more than just a connection—it is a testament to precision and craftsmanship. This focus on structural integrity ensures that each installation not only looks impeccable but also endures the test of time, even amidst South Africa’s diverse climate conditions. When joints are executed with care, they become the silent guardians of durability and aesthetic harmony, reinforcing the enduring versatility of acrylic sheets.

Aesthetic Considerations

In the realm of acrylic sheet applications, the significance of a flawless acrylic sheet joint cannot be overstated. It is the delicate thread that weaves strength and elegance into every installation, transforming mere panels into a harmonious masterpiece. An improperly executed joint not only compromises the structural integrity but also diminishes the aesthetic allure—something that’s vital in projects where clarity and visual purity are paramount.

When considering aesthetic considerations for an acrylic sheet joint, attention to detail is everything. A seamless joint enhances the illusion of a single, continuous surface, elevating the overall visual impact. For projects in South Africa’s diverse climate, the perfect acrylic sheet joint must also withstand environmental stresses without sacrificing beauty. This blend of resilience and refinement ensures that each installation remains captivating and durable over time.

To achieve this, professionals often focus on aspects like the precision of alignment, the choice of adhesive, and the finishing techniques used to smooth and conceal the joint. For instance, employing a high-quality, optical-grade adhesive can make the joint nearly invisible, creating a sleek, uninterrupted appearance. When executed with care, the acrylic sheet joint transforms from a simple connection into a work of craftsmanship, emphasizing clarity and elegance.

Durability and Longevity

In the grand tapestry of acrylic sheet applications, the significance of a proper acrylic sheet joint cannot be overstated. Behind every flawless installation lies a meticulous union—one that endures the test of time and the relentless South African climate. An improperly executed acrylic sheet joint is more than a mere flaw; it’s a silent threat to durability, risking cracks, warping, or delamination that can compromise the entire structure.

Durability and longevity hinge upon the craftsmanship of the joint—every bond must be resilient, flexible, and resistant to environmental stresses. When expertly crafted, the acrylic sheet joint becomes an unbreakable link, seamlessly blending strength with beauty. In regions where temperature fluctuations and humidity challenge materials daily, a well-executed joint acts as a fortress, safeguarding the integrity and clarity of your installation for years to come.

Types of Acrylic Sheet Joints

Butt Joints

When it comes to achieving a seamless aesthetic with acrylic sheets, the choice of acrylic sheet joint plays a pivotal role. Butt joints, in particular, stand out for their sleek, minimalist appeal—imagine the illusion of a continuous, glass-like surface uninterrupted by visible seams. These joints are meticulously crafted by aligning and bonding two sheets edge-to-edge, creating a clean, unobtrusive connection that enhances both form and function.

For those seeking precision and durability, the technique often involves using specialized adhesives or thermal welding, which ensures a robust acrylic sheet joint capable of withstanding daily wear. The process demands careful preparation; even the tiniest misalignment can compromise the visual harmony.

In South Africa, where versatile design solutions are in high demand, understanding the nuances of different types of acrylic sheet joints can significantly elevate project outcomes. Whether for display cases, partitions, or art installations, butt joints exemplify the marriage of elegance and engineering—testament to the timeless appeal of acrylic.

Overlap Joints

Overlap joints in acrylic sheet applications evoke a sense of effortless grace—like the gentle fold of a silk scarf draping over a surface, their seamless intersection whispering elegance. These joints are often chosen for their simplicity and quick assembly, where one sheet overlays another, creating a deliberate visual depth that can be both functional and artistic. The beauty of an acrylic sheet joint in this context lies in its versatility; it can be tailored to suit various design ambitions, from minimalist partitions to intricate display cases.

In practical terms, overlap joints provide an added layer of protection against environmental elements, shielding edges and enhancing structural resilience. Whether bonded with specialized acrylic adhesives or secured through mechanical fasteners, they deliver a balance of strength and aesthetic fluidity. For projects demanding a harmonious blend of form and function, the choice of overlap joints underscores a commitment to craftsmanship—an artistic yet pragmatic solution in the realm of acrylic sheet joint techniques.

Welded Joints

Welded joints in acrylic sheets reveal a hidden artistry—an intricate dance of heat and precision that results in a seamless, almost invisible connection. Unlike mechanical fastening or simple overlay methods, welded joints create a unified surface, enhancing both strength and aesthetic appeal. The process involves carefully heating the acrylic to a specific temperature, allowing the material to fuse at the molecular level, producing a bond that’s both durable and visually unobtrusive.

Within this realm, there are several distinguished types of acrylic sheet joints, each suited to different applications and design ambitions. For instance, the **butt joint** is favored for its clean, straightforward appeal, where two sheets are joined edge-to-edge. On the other hand, **extrusion welding** offers a robust solution, ideal for larger or more complex structures requiring high structural integrity. These techniques underscore the importance of selecting the right acrylic sheet joint for your project, ensuring longevity and flawless appearance.

For those seeking versatility and resilience, understanding the nuances of welded joints unlocks a new dimension of creative potential. Whether it’s a sleek display cabinet or a resilient partition, the choice of acrylic sheet joint plays a pivotal role in shaping the final outcome. The craftsmanship behind these joints often determines whether the finished piece stands the test of time or reveals subtle imperfections—an ongoing dance between art and engineering that keeps professionals continually captivated.

Mechanical Fastener Joints

In the realm of acrylic sheet joints, mechanical fastener joints stand as a testament to human ingenuity and practicality. Unlike welded joints, which fuse acrylic at a molecular level, mechanical fasteners rely on external hardware—screws, bolts, and rivets—to hold sheets together. This method offers the advantage of easy disassembly, making repairs or modifications more straightforward. However, it also introduces visible elements that can detract from the seamless aesthetic often desired in acrylic projects.

For those craving versatility, the choice of acrylic sheet joint through mechanical fastening can be refined with different styles.

- Surface-mounted bolts for a modern, industrial look

- Hidden fasteners for a cleaner, minimalist appeal

Each approach has its own story, its own expression of design intent. The key lies in understanding the balance between visual harmony and functional strength—where the integrity of the acrylic sheet joint is preserved without compromising the overall aesthetic.

Ultimately, the selection of a mechanical fastener joint reflects a deeper dialogue—between form and function, between practicality and artistry. It’s a dance that demands both technical precision and an intuitive sense of visual balance, especially when working within the unique context of South Africa’s diverse architectural landscape. Such joints serve as a reminder that even in the most engineered of creations, there is room for human touch and creative expression.

Adhesive Joints

In the shadowed corridors of architectural innovation, adhesive joints for acrylic sheets emerge as the silent architects of seamless beauty. Unlike their mechanical counterparts, these joints forge a bond at a molecular level, creating a virtually invisible connection that whispers of purity and precision. The art of acrylic sheet joint via adhesive introduces an element of mystique—each application a delicate dance of chemistry and craftsmanship.

The choice of adhesive can transform a simple sheet into a masterpiece of clarity and strength. Epoxy resins, acrylic solvents, or specialized acrylic adhesives are often employed to achieve a bond that withstands the test of time and elements. When executed with meticulous care, these joints offer a fluid, uninterrupted surface—ideal for projects demanding aesthetic purity.

For those seeking a harmonious blend of strength and subtlety, understanding the nuances of acrylic sheet joint adhesion is essential. The process may involve surface preparation, such as cleaning and lightly sanding, to ensure optimal adhesion. This layer of preparation can mean the difference between a fragile bond and a resilient, enduring connection that elevates the entire structure.

In the realm of acrylic sheet joints, the allure of invisibility often clashes with the need for durability. Yet, with the right adhesive, it becomes possible to marry these qualities—creating a joint that appears to vanish into the fabric of the design while remaining fiercely resilient. Such mastery of bonding elevates the craft, offering a poetic harmony between form and function.

Methods for Joining Acrylic Sheets

Solvent Cement Welding

Acrylic sheet joint techniques are crucial for ensuring a seamless and durable connection. Among the most effective methods is solvent cement welding, which chemically fuses sheets together, creating a virtually invisible joint. This process is preferred for its strength and clean appearance, making it ideal for transparent or aesthetic applications.

Solvent cement welding involves applying a special acrylic adhesive that dissolves the surface of the sheets, allowing the material to bond at a molecular level. The result is a joint that rivals the integrity of the acrylic itself. Proper surface preparation and precise application are essential to achieving a high-quality acrylic sheet joint.

For those seeking a quick, reliable solution, mechanical fasteners can complement solvent welding, especially in larger or load-bearing structures. This hybrid approach enhances durability while maintaining visual clarity. In every case, understanding the nuances of each acrylic sheet joint method guarantees long-lasting, professional results.

Ultrasonic Welding

Ultrasonic welding emerges as an intriguing method for creating a resilient acrylic sheet joint, especially where the darkness of innovation meets the light of precision. Unlike traditional techniques, ultrasonic welding harnesses high-frequency vibrations to generate heat within the material itself, causing the acrylic to melt and fuse at the molecular level. This process produces a joint that is as seamless as it is formidable, often indistinguishable from the surrounding material.

The true allure of ultrasonic welding lies in its speed and cleanliness—no messy adhesives or visible fasteners mar the surface. It is particularly suited for intricate or delicate acrylic sheet joint applications where aesthetics and strength must coexist in harmony. Moreover, this technique minimizes thermal distortion, preserving the clarity and integrity of the acrylic sheet.

For those seeking to expand the potential of their acrylic structures, understanding the parameters of ultrasonic welding can unlock a new dimension of craftsmanship. It is a method that embodies the dark elegance of modern engineering—powerful yet subtle, precise yet resilient.

Mechanical Fastening Techniques

When it comes to creating a strong, durable acrylic sheet joint, mechanical fastening techniques offer a reliable and versatile solution. These methods are often preferred for their ease of installation and capacity to hold large or heavy acrylic sheets securely in place. From bolts and screws to rivets, mechanical fasteners provide a tangible connection that can be easily adjusted or disassembled if needed.

In many applications, the choice of the right acrylic sheet joint depends on factors such as load-bearing requirements and aesthetic preferences. For instance, overlap joints are popular for their simplicity and visual appeal, while butt joints are favored for a seamless look. Sometimes, combining these methods with additional hardware, like spacers or backing plates, enhances the overall structural integrity.

Here’s a closer look at common mechanical fastening options for acrylic sheets:

- Screws and Bolts: The most straightforward solution, especially when working with thicker acrylic sheets.

- Rivets: Ideal for permanent fixtures where disassembly isn’t required.

- Clamps and Clips: Useful for temporary setups or when frequent adjustments are needed.

While mechanical fasteners may introduce visible elements into the design, they excel in providing flexibility and strength. Understanding the nuances of each method ensures that your acrylic sheet joint remains resilient against the stresses of everyday life, whether in a bustling workshop or a quiet rural setting. With the right approach, your acrylic structures will stand the test of time, beautifully blending function with form.

Adhesive Bonding

When it comes to creating a seamless acrylic sheet joint, adhesive bonding often steals the spotlight—mainly because it offers a clean, virtually invisible connection. Unlike mechanical fasteners that leave a visible footprint, adhesive joints can make your acrylic installation look sleek and professional. Plus, modern adhesives are specially formulated to handle the stresses and temperature variations typical in South African environments.

One popular method is solvent cement welding, which chemically fuses acrylic sheets together at a molecular level—think of it as the epoxy of the plastic world. This technique creates a durable, permanent acrylic sheet joint that resists cracking and peeling. Alternatively, UV-curing adhesives are perfect for projects that require precision and a quick set time, especially when working with clear acrylic sheets where transparency matters.

In some cases, using an ordered list can clarify the process:

- Prepare the surfaces thoroughly to ensure maximum adhesion.

- Apply the acrylic adhesive evenly along the joint line.

- Clamp or hold the sheets in place until the adhesive cures completely.

Whether you’re aiming for a seamless appearance or maximum strength, understanding the nuances of acrylic sheet joint bonding techniques can elevate your project from good to downright brilliant. After all, the right adhesive isn’t just about sticking two pieces together; it’s about forging a bond that lasts a lifetime—no matter what the South African climate throws at it.

Step-by-Step Guide to Acrylic Sheet Joining

Preparing the Acrylic Sheets

When it comes to creating a seamless acrylic sheet joint, preparation is everything—think of it as laying the foundation for a masterpiece. Skipping this step is like trying to build a house on quicksand; it’s destined to collapse. Start by thoroughly cleaning the acrylic sheets to remove dust, grease, and fingerprints that could sabotage your joint’s strength and clarity. A gentle abrasive or fine sandpaper can help create a slightly roughened surface, which significantly improves adhesion and weld quality.

Next, ensure the edges are perfectly aligned and free of any jagged or uneven cuts. Misaligned sheets are the bane of a professional-looking acrylic sheet joint, so precision here is non-negotiable. For optimal results, some experts recommend masking the edges with painter’s tape to prevent accidental damage during handling. Remember, the success of your acrylic sheet joint hinges on meticulous preparation; otherwise, even the best adhesive or welding technique might fall flat.

Choosing the Right Joint Type

Choosing the right acrylic sheet joint is crucial for ensuring both the structural integrity and aesthetic appeal of your project. Whether you’re assembling a display case or creating a striking architectural feature, the type of joint you select can dramatically influence the final outcome. An effective acrylic sheet joint must not only be strong but also maintain clarity and seamlessness—attributes that demand careful consideration.

For most applications, the decision hinges on factors like load-bearing requirements, visibility, and the environment. For instance, welded joints are ideal for creating a virtually invisible connection, perfect for transparent displays. Meanwhile, mechanical fastener joints offer versatility and ease of assembly, especially when disassembly might be needed later.

When choosing the appropriate joint type, consider the specific demands of your project and the characteristics of the acrylic sheet. Sometimes, a simple overlap joint suffices for lightweight applications, but for more demanding scenarios, a precision solvent cement weld might be necessary to achieve a durable, seamless bond. Remember, the right acrylic sheet joint isn’t just about strength—it’s about harmony between form and function, ensuring your creation withstands the test of time and use.

Executing the Joint

Joining acrylic sheets isn’t just a matter of slapping them together; it’s an art that combines precision with a dash of finesse. To achieve a flawless acrylic sheet joint, start with thorough surface preparation—clean, dry, and free of any grease or debris. This step ensures the adhesive or welding method bonds seamlessly, creating that coveted transparent, almost invisible connection.

Once prepped, executing the joint requires patience and attention to detail. For example, when using solvent cement welding, apply the cement carefully along the edge, then hold the sheets firmly in place. Remember, alignment is key—use clamps or jigs to keep everything neat and square. If mechanical fastener joints are your choice, opt for countersunk screws to maintain sleekness and avoid compromising the acrylic sheet joint’s clarity.

Whether you’re creating a display case or an architectural feature, knowing how to execute an acrylic sheet joint properly transforms a basic assembly into a work of art. The devil is in the details, after all—and a well-executed joint guarantees durability, aesthetics, and a touch of professional polish that turns heads. So, take your time, follow the steps meticulously, and let your craftsmanship shine through every acrylic sheet joint you craft!

Finishing and Curing

Finishing and curing an acrylic sheet joint is where craftsmanship truly comes to life, transforming a simple adhesion into a seamless masterpiece. After applying the adhesive or completing the welding process, patience is your greatest ally. Allow the joint to cure fully—this can range from several minutes to hours depending on the type of adhesive used. During this delicate phase, avoid disturbing the joint to ensure maximum strength and clarity.

To enhance robustness and aesthetics, some artisans opt for a gentle post-cure process, such as exposing the joint to controlled heat or UV light. This step can significantly improve the bond’s longevity and transparency. Remember, a well-cured acrylic sheet joint not only guarantees durability but also preserves the pristine visual flow—free from bubbles or imperfections.

For a flawless finish, consider the following steps:

- Ensure the joint remains undisturbed during curing.

- Use clamps or jigs for precise alignment and pressure.

- Maintain a dust-free environment to prevent debris from settling on the joint.

A meticulous approach to finishing and curing elevates your acrylic sheet joint from ordinary to extraordinary, echoing the artistry and precision behind every masterpiece you create.

Tips and Best Practices for Acrylic Sheet Joints

Surface Preparation

In the delicate dance of creating seamless acrylic sheet joints, surface preparation emerges as the silent maestro guiding the symphony of strength and clarity. A pristine, dust-free surface is paramount—any speck of debris or oil can compromise the integrity of the joint, leading to optical distortions or weak points that may not withstand time’s relentless march.

To achieve this, meticulous cleaning with isopropyl alcohol or a gentle solvent ensures that the acrylic’s surface is free of residues. Lightly sanding edges with fine-grit abrasive paper can also enhance adhesion, providing a micro-roughened surface that fosters a stronger bond. Remember, the goal is to strike a balance—rough enough to promote adhesion, yet smooth enough to preserve the acrylic’s luminous quality.

When preparing for an acrylic sheet joint, consider the environment as well—temperature and humidity levels should be optimal, avoiding extremes that could distort the material or hinder curing. This careful surface preparation is the foundation upon which the beauty and durability of an acrylic sheet joint are built, transforming mere assembly into an art of precision.

Climate and Environmental Conditions

In the intricate world of acrylic sheet joints, environmental conditions often whisper warnings that can undermine even the most meticulous craftsmanship. South Africa’s unpredictable climate—marked by intense heat, sudden humidity shifts, and occasional dust storms—demands an acute awareness of how these factors influence the integrity of your acrylic sheet joint. Extreme temperatures, for instance, can cause acrylic to expand or contract, risking stress fractures or misalignment if not managed properly.

Optimal conditions are essential for achieving pristine, durable joints. During the curing process, stable temperature ranges—typically between 18°C and 24°C—are ideal. Additionally, maintaining a humidity level below 60% minimizes the risk of condensation or surface contamination. When working outdoors, consider shading the work area or scheduling assembly during cooler parts of the day to prevent premature curing issues.

Remember, dust and airborne particles are not merely nuisances—they can embed into the adhesive or solvent weld, creating weak points that diminish clarity and strength. For large projects, creating a clean, controlled environment significantly improves the quality of the acrylic sheet joint, ensuring that the final structure withstands the test of time and elements.

Handling and Safety Precautions

Handling acrylic sheet joints with precision is a dance between art and science, where the slightest misstep can compromise the entire structure’s integrity. Proper safety precautions are paramount—wearing protective gloves and goggles shields against the fumes and potential splinters that can arise during assembly. Working in a well-ventilated space not only ensures your safety but also preserves the clarity of the acrylic sheet joint, preventing surface contamination that weakens the bond.

In addition, maintaining a clutter-free workspace minimizes dust accumulation, which is notorious for embedding into adhesives and undermining the joint’s strength. When working outdoors in South Africa’s unpredictable climate, consider the following:

- Use shaded areas to regulate temperature fluctuations.

- Schedule bonding activities during cooler parts of the day.

- Ensure the environment remains clean and free of airborne debris.

Taking these precautions ensures the acrylic sheet joint remains pristine, ultimately extending the lifespan of your project. The delicate balance of environmental awareness and meticulous handling can elevate your craftsmanship from good to exceptional, transforming simple joints into enduring masterpieces.

Troubleshooting Common Issues

Even the most meticulously crafted acrylic sheet joint can succumb to unforeseen issues if troubleshooting isn’t approached with care. One common challenge is cloudiness or fogging around the joint, often caused by improper surface preparation or residual contaminants. Ensuring the acrylic surfaces are thoroughly cleaned with isopropyl alcohol before bonding can make a significant difference in achieving a crystal-clear joint.

Another frequent problem is weak adhesion or joint failure, which may stem from environmental factors or incorrect curing times. For outdoor installations in South Africa’s unpredictable climate, it’s wise to verify that the adhesive used is suitable for external conditions and to allow adequate curing time in cooler, shaded environments.

When tackling issues with an acrylic sheet joint, consider these troubleshooting steps:

- Inspect the surface for scratches or debris that could impair adhesion.

- Ensure the joint has been properly aligned and clamped—misalignment weakens the bond over time.

- Evaluate environmental conditions—excessive heat or humidity can compromise the joint’s integrity.

Addressing these common issues early preserves the strength and aesthetic appeal of your acrylic sheet joint, transforming a potential flaw into a testament of craftsmanship. Remember, patience and precision are the true artisans behind durable, flawless joints.

Choosing the Right Adhesive or Welding Technique

Factors to Consider

Choosing the right adhesive or welding technique for an acrylic sheet joint is more than a matter of convenience; it is a question of integrity and purpose. The decision hinges on understanding the unique demands of the application—whether it’s a display case that demands clarity or a structural element that requires strength.

In essence, the acrylic sheet joint must balance aesthetic appeal with the constraints of environmental conditions. For instance, solvent cement welding offers a seamless, transparent bond ideal for decorative panels, while ultrasonic welding provides a sturdy, chemical-free connection suitable for high-stress environments.

Factors such as the thickness of the acrylic sheet, exposure to UV rays, and load-bearing requirements influence the choice. To simplify, consider this sequence:

- Assess the environment and load conditions.

- Select the appropriate adhesive or welding technique based on the joint’s purpose.

- Ensure proper surface preparation to achieve a durable acrylic sheet joint.

Ultimately, the strength of the acrylic sheet joint reflects a deeper understanding of material science and human craftsmanship—an intersection where innovation meets reliability, and where every detail matters.

Advantages and Disadvantages

Choosing the right adhesive or welding technique for an acrylic sheet joint can make the difference between a durable, professional finish and a costly failure. Each method offers distinct advantages tailored to specific needs. For example, solvent cement welding creates a seamless, crystal-clear bond—perfect for decorative displays—while ultrasonic welding delivers a robust, chemical-free connection suitable for high-stress environments.

However, it’s essential to weigh the disadvantages as well. Solvent cement welding, though aesthetically pleasing, can be vulnerable to UV degradation if not properly treated. Ultrasonic welding, on the other hand, requires specialized equipment and expertise, which may increase initial costs.

- Ease of application

- Environmental resistance

- Strength and durability

Ensuring the right balance hinges on understanding these trade-offs and matching them with the specific demands of your acrylic sheet joint. When approached thoughtfully, selecting the appropriate technique enhances both the integrity and longevity of the finished product—vital for projects across South Africa’s diverse climates and industries.

Maintenance and Repair of Acrylic Sheet Joints

Regular Inspection

Maintaining the integrity of an acrylic sheet joint is crucial for ensuring long-term performance. Regular inspection helps identify early signs of wear, cracking, or joint failure. Over time, environmental factors like UV exposure and temperature fluctuations can weaken the bond, making routine checks indispensable.

During inspections, look for discoloration, clouding, or any separation at the joint. These issues often indicate adhesive degradation or mechanical stress. Spotting problems early can prevent costly repairs and extend the lifespan of the acrylic sheet joint. For optimal results, clean the surface thoroughly before inspecting and handle the acrylic sheets with care to avoid introducing new damage.

In some cases, minor repairs such as reapplying adhesive or tightening mechanical fasteners are sufficient. For more extensive damage, partial replacement of the joint or entire sheet might be necessary. Keeping detailed records of maintenance activities ensures that any recurring issues are promptly addressed, preserving the aesthetic and structural integrity of the acrylic installation.

Repair Methods

When it comes to maintaining the longevity of your acrylic sheet joint, repair methods are a crucial aspect that often gets overlooked—until a crack or separation appears like an unwelcome guest at a party. Fortunately, most issues can be remedied with a little know-how and the right materials. For minor damages, adhesive reapplication or tightening mechanical fasteners can do wonders, restoring strength and visual appeal without the need for a full overhaul.

If the damage is more severe, consider performing solvent cement welding or ultrasonic welding techniques. These methods fuse the acrylic sheets at the molecular level, creating a seamless and robust acrylic sheet joint that can withstand environmental stressors—think UV exposure or temperature swings—and look as pristine as the day it was installed. Here’s a quick rundown of repair options:

- Reapplying specialist acrylic adhesive

- Replacing damaged sections of the joint

- Using mechanical fasteners for temporary fixes

- Opting for advanced welding techniques like ultrasonic welding

In some cases, a partial or complete replacement of the acrylic sheet joint might be necessary if the damage is widespread. Whatever the approach, proper surface preparation—cleaning and roughening the area—is essential for ensuring a durable repair. Remember, a well-executed repair not only extends the lifespan of the acrylic sheet joint but also preserves its aesthetic integrity, making your investment worth every cent!

Preventive Measures

Maintaining the integrity of your acrylic sheet joint is a delicate dance between vigilance and care. Preventive measures serve as the silent guardians, warding off the subtle encroachments of wear and tear that threaten longevity. Regular inspection reveals the earliest signs of stress—tiny cracks or looseness—that, if caught early, can be easily remedied before escalating into costly repairs. The key lies in understanding the environment in which your acrylic sheet joint exists. Exposure to harsh sunlight, temperature fluctuations, or chemical agents can weaken bonds over time, making proactive protection essential.

To bolster your acrylic sheet joint’s resilience, consider implementing routine surface cleaning and gentle roughening techniques before any repair. This ensures that adhesives or welding methods adhere seamlessly, creating a bond that resists environmental assault. For added peace of mind, employing protective coatings or UV-resistant treatments can serve as an invisible shield, preserving the joint’s clarity and strength. Remember, a well-maintained acrylic sheet joint is not just about immediate aesthetics—it’s about safeguarding your investment against the relentless march of time and nature’s unpredictable whims.

FAQs About Acrylic Sheet Joints

What is the strongest way to join acrylic sheets?

When it comes to forging a resilient union between acrylic sheets, the question often arises: what is the strongest way to join acrylic sheets? In the realm of craftsmanship, not all joints are created equal—some whisper strength, while others roar endurance. The pinnacle of durability is achieved through solvent cement welding, a method that fuses acrylic sheets at a molecular level, creating a seamless, nearly invisible bond that rivals the integrity of the material itself. This technique is revered for its ability to deliver a joint that withstands environmental stresses and mechanical strains alike.

For those seeking a steadfast acrylic sheet joint, understanding the nuances of each method is essential. Mechanical fastener joints, for example, offer ease but may introduce stress points, whereas adhesive joints provide a clean finish but depend heavily on surface preparation. Ultimately, the strongest joint hinges on precise execution, proper choice of adhesive or welding method, and meticulous surface preparation. When done correctly, the acrylic sheet joint becomes more than just a connection—it transforms into a testament of craftsmanship and resilience, echoing the enduring spirit of South African ingenuity.

Can acrylic sheet joints be waterproof?

One common query surrounding acrylic sheet joints is whether they can be waterproof. The answer hinges on the method of joining and the materials used. When properly executed, an acrylic sheet joint can indeed be waterproof, making it suitable for applications exposed to moisture, such as aquariums, shower screens, or outdoor signage. The secret lies in the technique—welding with solvent cement creates a molecular bond that seals the joint seamlessly, preventing water ingress.

However, not all joints are inherently waterproof by default. Mechanical fastener joints, for instance, may require additional sealing measures like rubber gaskets or waterproof sealants to ensure water tightness. For an optimal waterproof acrylic sheet joint, surface preparation is crucial; clean, smooth surfaces promote better adhesion and reduce potential leak points. Ultimately, the integrity of the joint depends on meticulous craftsmanship, ensuring the acrylic sheet joint remains resilient against the relentless forces of water and weather.

How long do acrylic sheet joints last?

In the realm of acrylic sheet joints, durability is often a question that lingers like a whisper in the wind. Wonder no more—these joints, when crafted with precision and care, can stand the test of time. Typically, an expertly executed acrylic sheet joint can last anywhere from 10 to 20 years, depending on the environment and maintenance. The secret to longevity lies in the method of joining and the quality of materials used, which forge a bond resilient against the relentless march of weather and wear.

Environmental factors play a pivotal role—exposure to UV rays, temperature fluctuations, and moisture can erode lesser joints prematurely. Yet, with proper surface preparation and the right choice of adhesive or welding technique, the lifespan of an acrylic sheet joint can be significantly extended. Regular inspection and timely repair ensure that the integrity of the joint remains unshaken, transforming a simple connection into a monument of durability.

Ultimately, the question isn’t just about how long an acrylic sheet joint lasts, but how well it is crafted. A meticulously bonded joint, free of imperfections and sealed tightly, can serve faithfully for decades, turning visions into enduring reality—whether for signage, aquariums, or outdoor installations. The true magic lies in the craftsmanship, a testament to the art of joining acrylic with finesse and precision.

Are special tools needed for joining acrylic sheets?

When contemplating the art of joining acrylic sheets, one question resonates like a quiet drumbeat—are special tools necessary for achieving a seamless acrylic sheet joint? The answer is both nuanced and fascinating. In many cases, the answer depends on the complexity of the joint and the method chosen. For simple adhesive bonds or solvent cement welding, no specialized tools beyond basic preparation equipment are required. However, for more intricate or high-strength joints, precision tools such as acrylic welders, clamps, or even ultrasonic welding devices can elevate the quality of the bond to an art form.

Particularly in South Africa, where outdoor exposure and environmental conditions demand resilience, investing in the right tools can make all the difference. For example, when creating a waterproof acrylic sheet joint—crucial for aquariums or outdoor signage—the use of specialized welding equipment ensures a durable, airtight bond. The selection of tools and techniques is not merely about convenience but about forging a connection that endures the test of time and weather.

In essence, while many acrylic sheet joints can be assembled with standard tools and adhesives, the choice of whether to employ special tools ultimately hinges on the desired strength, clarity, and longevity of the joint. Mastery over both the materials and the method transforms a simple connection into a resilient masterpiece—worthy of the most demanding applications, from vibrant signage to expansive outdoor installations. Every detail, every tool, and every technique plays a pivotal role in the enduring beauty and strength of the acrylic sheet joint.

0 Comments